To engrave tumblers without wobble or skips, start by ensuring your rotary attachment is compatible, secure, and properly calibrated. Use custom grips or fixtures to hold the tumbler firmly and check alignment with laser guides or calipers. Adjust your rotation speed and pressure gradually on scrap material to find the perfect balance. Regularly inspect, maintain, and fine-tune your setup for best results. Keep going to discover more tips that will help you achieve flawless, wobble-free engravings.

Key Takeaways

- Ensure proper tumbler fit with custom grips or clamps to prevent wobble during rotation.

- Verify alignment using laser guides or calipers, and calibrate the rotation axis precisely.

- Adjust rotation speed and pressure gradually, testing on scrap material to prevent skips and wobbling.

- Regularly inspect and tighten all attachment and adjustment points for stability and smooth operation.

- Use vibration damping and environmental controls to minimize external influences on engraving accuracy.

Why Proper Setup Ensures Wobble-Free Tumblers

Properly setting up your rotary attachment is essential because it directly affects the stability of your tumblers. When you choose the right material, you guarantee the tumbler fits securely, reducing wobbling during engraving. Color accuracy impacts overall image quality. Stable material selection minimizes vibrations that can cause skips or uneven patterns. Additionally, a proper setup ensures your engraving patterns come out crisp and consistent. If your tumbler isn’t snug, even the best design won’t appear clearly, and you risk damaging the surface. Make sure the attachment is aligned correctly and the tumbler is firmly secured before starting. Using precise measurement tools can help achieve optimal alignment and stability. This attention to detail keeps the tumbler steady, allowing you to achieve precise, professional results without wobble or distortion. Proper setup is the foundation for high-quality engraving every time, and understanding the importance of material stability can greatly enhance your results. Ensuring the secure attachment is tight and properly aligned minimizes movement and helps produce clean, accurate engravings. Additionally, regularly checking the adjustment points can prevent misalignment during longer engraving sessions.

Choosing the Right Rotary Attachment and Accessories

When choosing a rotary attachment, you need to guarantee it’s compatible with your machine to avoid issues later on. Picking the right accessories, like extension arms or specific grips, can make your work more efficient and precise. Focus on selecting essentials that match your projects to get the best results and smooth operation. Additionally, ensuring your setup supports local automation and cross-platform integration can streamline your workflow and enhance overall productivity. Incorporating smart appliance connectivity can further optimize your engraving process by enabling remote adjustments and monitoring. Being aware of compatibility considerations helps prevent technical problems and ensures seamless operation across different devices. Understanding equipment compatibility is crucial for maintaining reliable and consistent engraving outcomes. To maximize your setup’s effectiveness, consider how power tool features align with your project requirements for optimal performance.

Compatibility With Machine

Choosing the right rotary attachment begins with guaranteeing compatibility with your machine. First, verify your device’s specifications, such as the motor type and size, to match the rotary motor’s requirements. Second, check if your engraving software supports the rotary attachment, as not all programs are compatible with every model. Third, confirm the attachment’s mounting options and weight capacity, ensuring it fits securely and won’t strain your machine. This step guarantees smooth operation and prevents damage. Compatibility also means understanding your machine’s control system and ensuring it can handle the rotary motor’s power. Additionally, understanding machine compatibility considerations can help you select the best setup for your specific equipment, avoiding costly mistakes and ensuring precise, wobble-free engraving on tumblers. Proper compatibility is essential for achieving professional results efficiently and to prevent wobble or skips during operation. Being aware of the essential specifications of your equipment can further aid in making an informed choice and optimizing your engraving process.

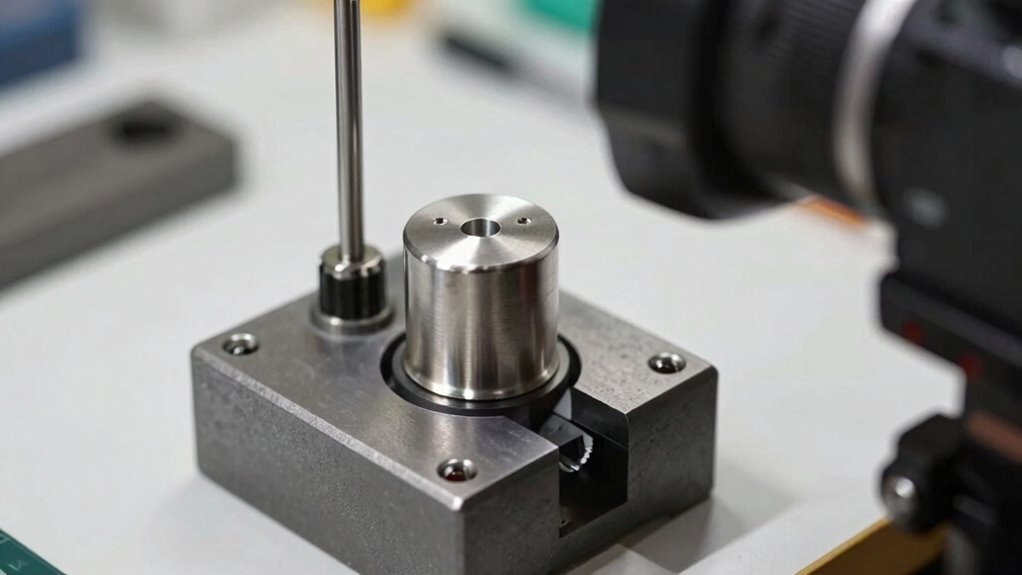

Selecting Essential Accessories

Selecting the right rotary attachment and accessories guarantees you get the best results for your projects. When choosing tools for custom engraving, consider the materials you’ll work with, like glass, metal, or plastic. Different materials require specific attachments or adjustments to ensure precision and avoid wobble or skips. For example, soft materials may need softer grips, while rigid materials need sturdy clamps. Accessories such as adjustable chucks, foam padding, and specialized holders help stabilize items and improve accuracy. Properly matching your rotary attachment to your machine and project needs minimizes errors and enhances quality. Always evaluate the material considerations before purchasing accessories to guarantee compatibility and peak performance. This careful selection process is key to achieving professional, clean engravings every time. Additionally, understanding the material compatibility of your accessories can prevent damage and ensure consistent results, especially when working with diverse material types found in various projects. Being aware of adjustment techniques can further optimize your setup and improve engraving precision. Incorporating proper maintenance of your attachments also extends their lifespan and maintains engraving quality over time. Moreover, selecting accessories with adjustable features allows for fine-tuning and greater control during engraving.

Preparing Your Tumbler for Stable Engraving

To guarantee a clear and precise engraving, you need to prepare your tumbler for stability. First, ensure you use a custom grip designed for your tumbler’s shape; this prevents wobble during engraving. Second, check material compatibility—verify your tumbler’s surface works well with the engraving process and doesn’t cause slipping. Third, secure the tumbler firmly in the rotary attachment, avoiding loose fittings that can shift or wobble. These steps help maintain consistent contact and prevent skips or blurred lines. Proper preparation minimizes vibrations and ensures your design stays aligned throughout the process. Additionally, understanding sound therapy techniques and how they work can help you better grasp the technical aspects of equipment setup. Taking these precautions guarantees professional results and reduces the need for rework. Being aware of filtration and airflow can also improve your overall engraving environment by reducing dust and debris. To further enhance stability, consider using vibration damping methods to minimize equipment movement during engraving. Focus on these essentials for a smooth, accurate engraving experience.

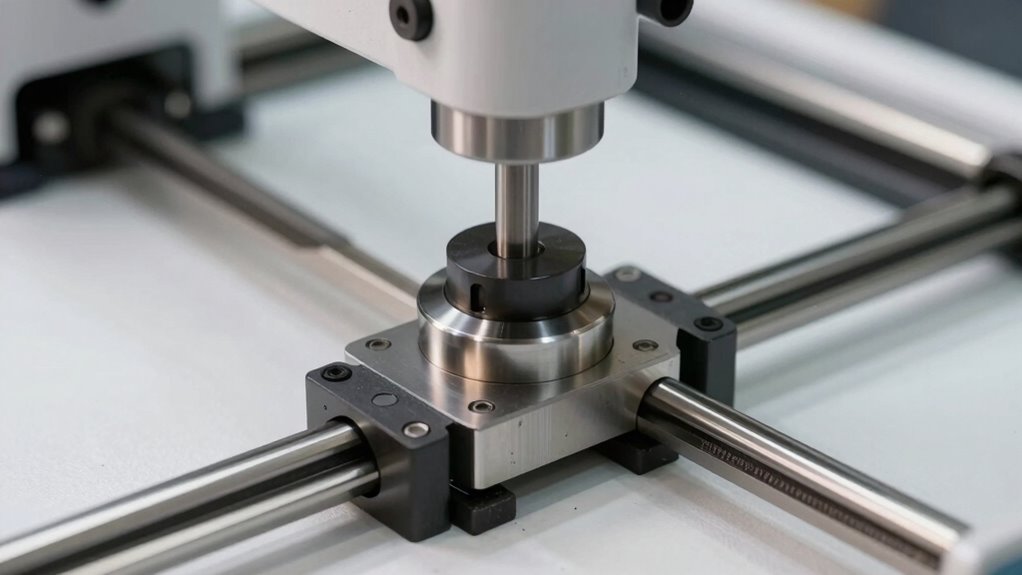

How to Align the Rotary Attachment Correctly

Proper alignment of the rotary attachment guarantees your engravings are precise and consistent. Start by using alignment tools designed for your machine, such as laser guides or calipers, to ensure the tumbler is centered and level. Perform a thorough rotary calibration by checking that the axis of rotation matches the machine’s laser or alignment marks. Adjust the clamps and rotation mechanism until the tumbler spins smoothly without wobble. Confirm that the engraving surface is perpendicular to the laser beam for even results. Take your time to double-check the alignment from multiple angles. Regular calibration helps maintain accuracy and alignment are key to flawless engravings. Additionally, verifying that the rotation speed is correctly set ensures smooth operation and prevents skips during engraving. Ensuring the proper setup of your rotary attachment reduces the chances of errors and improves overall engraving quality. Paying attention to machine maintenance can further enhance the precision and longevity of your setup.

Setting Speed and Pressure for Optimal Results

Adjusting the speed and pressure settings is essential to achieving clean, precise engravings on your tumblers. Proper speed adjustment ensures the engraving process is smooth without skips or wobble, while pressure calibration guarantees the design penetrates the surface evenly. To enhance these settings, consider these steps:

Optimizing speed and pressure ensures smooth, professional tumbler engravings with consistent, even results.

- Start with a moderate speed and gradually increase until the engraving is consistent.

- Adjust pressure calibration so the tip applies firm, even contact without pressing too hard.

- Test on scrap material, then fine-tune the speed adjustment and pressure until the desired clarity is achieved.

Keep in mind, the right balance prevents damage and ensures professional results. Regularly revisit your settings as you work with different materials or designs to maintain ideal performance.

Testing and Fine-Tuning Your Rotary Setup

Before finalizing your rotary setup, it’s crucial to test your settings on scrap material that closely resembles your actual workpieces. Use various rotary attachment materials to identify any issues with wobble or skips. Adjust your engraving software settings, paying attention to speed, power, and rotation direction. Verify that the design appears centered and smooth on the test piece before proceeding. Fine-tuning may involve small tweaks to your clamps, material positioning, or software parameters. Keep detailed notes of each adjustment to track what works best. This process helps prevent costly mistakes and guarantees your finished engravings are clean and professional. Remember, thorough testing on representative materials saves time and guarantees your setup is optimized for flawless results.

Troubleshooting Wobble and Skip Problems

Wobble and skip issues are common problems that can compromise the quality of your engravings, but they are often fixable with targeted troubleshooting. To address these problems, consider the following steps:

- Check your material selection—ensure the tumbler is securely mounted and compatible with your engraving techniques.

- Adjust the rotary attachment’s positioning to eliminate any loose parts or misalignments causing wobble.

- Review your engraving settings—reduce engraving speed or pressure to prevent skips caused by aggressive techniques.

Maintaining Your Rotary Setup for Long-Term Success

To guarantee your rotary attachment remains reliable over time, regular maintenance is essential. Consistently perform rotary maintenance by inspecting the device for wear, tightening loose components, and cleaning debris that could cause wobble or skips. Lubricate moving parts as needed to ensure smooth operation. Upgrading accessories, such as high-quality bearings or clamps, can enhance stability and longevity. Keep a schedule for routine checks and maintenance tasks to prevent issues before they start. Proper care extends the lifespan of your rotary setup and ensures precise, consistent engravings. Remember, well-maintained equipment reduces downtime and improves your overall workflow. By staying proactive with rotary maintenance and considering strategic accessory upgrades, you set yourself up for long-term success and flawless results.

Frequently Asked Questions

Can I Use a Rotary Attachment on Different Tumbler Sizes?

Yes, you can use a rotary attachment on different tumbler sizes, thanks to its attachment versatility. To guarantee tumbler compatibility, adjust the attachment securely for each size, preventing wobble or skips during engraving. Take time to reposition the tumbler properly each time, and verify stability before starting. This way, you get consistent, high-quality results across various tumbler sizes without needing a new setup.

What Safety Precautions Should I Follow During Setup?

Imagine yourself in a well-lit workspace, where safety gear like goggles and gloves shield you from potential hazards. You should always unplug the machine before adjusting the rotary attachment, ensuring electrical safety. Wear protective gear to guard against debris or sparks. Keep your workspace tidy, and double-check all connections. By staying alert and cautious, you minimize risks, making your engraving process safe and successful every time.

How Often Should I Calibrate My Rotary Attachment?

You should calibrate your rotary attachment regularly, ideally every few months or whenever you notice engraving issues. Consistent calibration guarantees ideal rotary compatibility and prevents wobble or skips. If you change tumblers or equipment, recalibrate immediately. Frequent calibration maintains accuracy, especially if you notice uneven engraving or vibrations. By staying on top of calibration, you keep your setup precise, ensuring professional results and extending your rotary attachment’s lifespan.

Are There Specific Tools Recommended for Precise Alignment?

You should use alignment tools and adjustment guides to guarantee precise setup. A dial indicator helps check for wobble, while a straightedge or laser guide assists with proper alignment. These tools make it easier to position your rotary attachment accurately, preventing skips and wobble during engraving. Regularly using these tools ensures consistent results and prolongs your equipment’s lifespan, giving you clean, professional engravings every time.

Can I Engrave Other Shapes Besides Tumblers With This Setup?

Yes, you can engrave other shapes besides tumblers with this setup. Just make certain your rotary attachment is compatible with different materials and shapes. You might need to adjust the engraving techniques slightly, depending on the alternative materials you’re working with, to achieve a clean, precise result. Proper alignment is essential for consistent results across various objects, so take your time setting up each piece to prevent wobble or skips.

Conclusion

With the right setup, engraving tumblers becomes smooth and hassle-free. Sure, it might seem tricky at first, but once you master alignment and settings, wobble and skips are a thing of the past. Don’t worry if it takes a few tries—practice makes perfect. Keep your equipment maintained, and soon you’ll enjoy flawless, professional-looking engravings every time. Stick with it, and you’ll be creating stunning tumblers with ease and confidence.