When choosing between water-based and plastisol inks, you’ll find water-based inks eco-friendly, softer, and easier to clean, but less durable, especially on dark fabrics. Plastisol offers vibrant, long-lasting colors, with a thicker, more rigid feel, ideal for durability but less eco-friendly. Each has its strengths and drawbacks, so understanding the differences helps you select the best option for your project’s needs. Keep exploring to uncover the details behind these popular inks.

Key Takeaways

- Water-based inks are eco-friendly, softer, and absorb into fabric, while plastisol sits on the surface for durability and vibrant opacity.

- Plastisol is more opaque and long-lasting but involves complex cleanup and environmental concerns due to PVC content.

- Water-based inks are easier to clean with water, suitable for detailed and natural-looking designs, but less durable on dark fabrics.

- Plastisol provides bold, vibrant colors with excellent durability, ideal for high-wear garments, but feels thicker and less breathable.

- Beginners should consider project goals: eco-friendliness and softness favor water-based, while durability and vibrancy favor plastisol.

What Are Water-Based and Plastisol Screen Printing Inks?

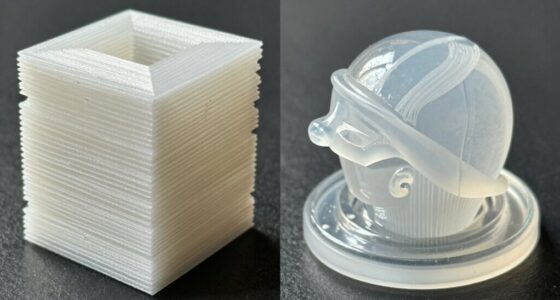

Have you ever wondered what sets water-based and plastisol inks apart in screen printing? Water-based inks are often considered eco-friendly options because they contain fewer chemicals and are easier to clean up. They penetrate the fabric, resulting in softer prints that feel more natural. Plastisol inks, on the other hand, are made from PVC and plasticizers, which create vibrant, opaque colors. The curing process for plastisol involves heat to fully cure the ink, making it durable and long-lasting. Water-based inks cure through absorption into the fabric, often requiring longer or specific drying methods. Both types have unique qualities that influence their environmental impact and application, helping you choose the right ink based on your project’s sustainability goals and production needs. European cloud infrastructure offers innovative solutions for sustainable and secure printing processes.

How Do Water-Based and Plastisol Inks Differ in Composition and Use?

You’ll notice that water-based and plastisol inks differ mainly in their composition, which affects how you apply them and the final result. Water-based inks are made with water and pigments, making them easier to work with on certain fabrics, while plastisol contains PVC and plastisol resins for a more durable, plastic-like feel. These differences influence not only application techniques but also how long the prints last and how they feel on the finished product. Additionally, color accuracy plays a role in ensuring the printed design appears vibrant and true to the intended shades. Understanding ink composition helps in choosing the right type for different projects and desired outcomes, and considering regulatory compliance is important when selecting inks for commercial use. Moreover, knowing about environmental impact can guide you toward more sustainable printing options. Being aware of body jewelry materials and their effects on skin health can also be beneficial when working with inks that may come into contact with sensitive areas or garments worn close to the skin.

Ink Composition Differences

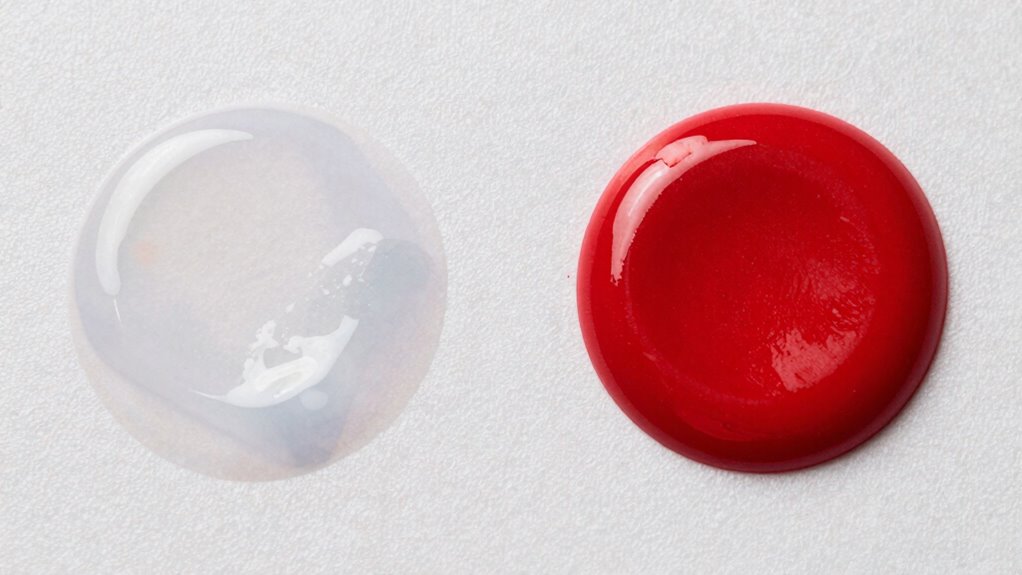

Water-based and plastisol inks differ fundamentally in their composition, which directly impacts how they perform and are used in printing. Water-based inks rely on an ink binder dissolved in water, allowing the pigment suspension to bond with fabric fibers. In contrast, plastisol contains PVC particles suspended in a plasticizer, forming a thick, durable layer on the surface. This composition makes water-based inks eco-friendly and easier to clean but less opaque. Plastisol offers vibrant colors and flexibility but requires heat curing. The table below highlights these emotional differences:

| Aspect | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Eco-friendliness | Gentle, minimal chemicals | Contains PVC, less eco-friendly |

| Ease of Use | Simple cleanup, less equipment | Durable, requires heat curing |

| Color Brightness | Softer, more transparent | Vivid, opaque colors |

| Texture | Soft, breathable finish | Thick, plastic-like feel |

| Durability | Less resistant to cracking | Long-lasting, flexible coating |

Application Techniques Variations

Because of their differing compositions, water-based and plastisol inks require distinct application techniques to achieve ideal results. Water-based inks tend to soak into the fabric, making even application and smooth ink layering essential for vibrant prints. You’ll want to use a softer squeegee pressure and thinner coats to prevent excessive ink buildup. In contrast, plastisol inks sit on top of the fabric, allowing for more aggressive application and thicker ink layers without bleeding. This makes ink layering easier, especially for achieving bold, opaque designs. When applying plastisol, you can use a firmer squeegee and multiple passes to build up color intensity. Mastering these application techniques differences guarantees your prints look professional and adhere properly, no matter which ink type you’re using.

Durability and Feel

The durability and feel of ink on fabric largely depend on their compositions. Water-based inks typically produce a softer fabric feel because they penetrate the fibers, resulting in a lightweight, breathable print. They’re generally less durable over time, especially after multiple washes, but their ink softness offers a more comfortable wear. Water-based inks also tend to be more environmentally friendly, aligning with sustainable art practices. Plastisol inks, on the other hand, sit on the surface of the fabric, creating a thicker, more rigid feel. This makes them highly durable and resistant to cracking or fading, but it can compromise the fabric feel, making the print feel heavier or stiffer. If you want a softer, more natural feel, water-based inks are preferable. For durability and vibrant colors, plastisol inks excel, though they may sacrifice some ink softness. Reversible motor ceiling fans, for example, can enhance the longevity of the printed design by reducing heat buildup during the year. Additionally, understanding ink composition helps in selecting the appropriate type for specific project needs.

Which Ink Is Better for Your Screen Printing Projects?

When choosing the right ink for your screen printing projects, you need to consider durability, color vibrancy, and ease of application. Water-based inks often offer softer finishes and a broader color range, while plastisol inks tend to be more durable and long-lasting. Think about which factors matter most to you to determine the best fit for your needs. Additionally, understanding the application process can help you select the most suitable ink type for your specific project. Knowing the printing techniques involved can also influence your choice, ensuring optimal results and efficiency. Being aware of the printing surface can further guide your decision, as different surfaces may respond better to one ink type over another. Considering the environmental impact of each ink can also be important for sustainable practices. Moreover, the cost and ease of cleanup are additional factors to weigh, especially if you are working within budget constraints or aiming for a more eco-friendly workflow.

Durability and Longevity

Durability and longevity are essential factors to take into account when choosing between water-based and plastisol inks for your screen printing projects. Plastisol ink generally offers superior durability, maintaining fabric stiffness and resisting cracking or fading over time. It’s less affected by washing and wears well, making it ideal for garments that endure frequent use. Water-based inks, while more eco-friendly, can sometimes be less durable, especially on certain fabrics, leading to potential issues with fabric stiffness and color retention after multiple washes. However, with proper curing and quality formulations, water-based inks can still provide respectable longevity. Additionally, understanding the lease terms and proper application techniques can influence the overall durability of your printed designs. Ultimately, your choice depends on your project’s demands—if durability and long-lasting color retention are top priorities, plastisol is often the safer bet.

Color Brightness and Range

Are you wondering which ink offers the most vibrant colors for your screen printing projects? Water-based inks typically provide a wide spectrum of vibrant colors that look softer and more natural on garments. They blend easily and can produce subtle shades that enhance detailed designs. Plastisol inks, on the other hand, are known for their bold, opaque colors that pop vividly on fabric. They generally have a broader color range, especially for bright, eye-catching hues, making them ideal for designs that demand maximum impact. If your goal is to achieve striking, highly saturated prints, plastisol might be the better choice. However, for a more nuanced color palette with a softer finish, water-based inks excel. Color brightness and range are key factors to consider, and choosing the right ink depends on your desired visual effect and the specific aesthetic you want to achieve.

Ease of Use

Choosing the right ink depends not only on color qualities but also on how easy they are to work with during your screen printing process. Water-based inks are generally simpler to clean up because their cleanup process involves water and soap, making them more beginner-friendly. They also require less complex mixing techniques since they’re ready to use or need minimal thinning. Additionally, water-based inks tend to adhere better to various fabrics, which can be advantageous for different types of projects. The ease of application is another factor that beginners should consider, as it can influence the overall quality and speed of production. Plastisol inks, on the other hand, demand a more careful mixing process, often involving thickening or thinning with specific additives. Cleanup for plastisol is messier, requiring solvents or special cleaners, which can be time-consuming. Overall, water-based inks tend to be easier to handle, especially if you’re just starting out, while plastisol’s handling and cleanup process can be more involved but offers different advantages once you’re experienced. Additionally, ease of use plays a significant role in choosing the right ink for your projects, especially when considering your level of experience and the complexity of your designs. For beginners, understanding the cleaning process can significantly impact your workflow and overall project success.

Pros and Cons of Water-Based Ink for Screen Printing?

Water-based ink offers several advantages for screen printing, making it an appealing choice for many artists and printers. One major benefit is that it’s considered an eco-friendly option, as it produces less toxic fumes and waste compared to plastisol. This can help reduce your environmental impact and create a safer workspace. Additionally, water-based inks tend to have lower material costs, which can be a plus if you’re working on a tight budget. They also produce softer prints that feel more natural on the fabric. However, water-based ink can be trickier to work with, especially on dark garments, and may require more skill to achieve vibrant colors. Understanding water chemistry is essential for achieving optimal results with water-based inks. Proper preparation and knowledge of ink formulation can greatly improve your printing outcomes, especially considering film formation and how it affects ink adhesion and durability.

Pros and Cons of Plastisol Ink for Screen Printing?

Plastisol ink remains a popular choice for screen printing because it offers vibrant colors, excellent opacity, and ease of use. Its durability makes it ideal for producing long-lasting designs on various garments. However, it has drawbacks, especially regarding environmental impact. Unlike eco-friendly alternatives, plastisol contains PVC and phthalates, which can release harmful chemicals during printing and disposal. This raises concerns about sustainability and health risks for printers and consumers. Additionally, plastisol requires a plastisol-specific cleaner, often solvent-based, increasing VOC emissions. While it’s easy to work with and widely available, it’s important to weigh these environmental considerations. environmental impact is an important consideration when choosing inks for screen printing. Considering the safety of the materials used can help prevent health issues for those handling and wearing printed items. Furthermore, many printers are exploring eco-friendly inks as sustainable alternatives to reduce harmful emissions and improve safety.

Furthermore, advancements in AI tools can assist in selecting more sustainable inks and improving overall environmental practices within the industry.

How to Choose the Right Ink: Water-Based or Plastisol?

Deciding between water-based and plastisol inks depends on your priorities for the project. If eco-friendly options matter most, water-based inks are a better choice because they typically contain fewer chemicals and are easier to wash away, making them more environmentally friendly. However, consider your budget and cost considerations: plastisol inks often cost less upfront and are more durable, especially on darker fabrics. Water-based inks can be more expensive and may require more skill to achieve vibrant, long-lasting prints. Think about your desired print quality, production volume, and sustainability goals. If you’re aiming for an eco-conscious approach, water-based inks are ideal; for cost efficiency and durability, plastisol is often the better option. Choose based on what aligns best with your project needs. Smart home automation can also help streamline production processes and optimize resource use.

Frequently Asked Questions

Can Water-Based Inks Be Used on All Fabric Types?

Yes, water-based inks can be used on most fabric types, but fabric compatibility varies. They work best with natural fibers like cotton because of their ink absorption qualities, which guarantee vibrant, long-lasting prints. However, on synthetic fabrics like polyester, water-based inks may not adhere as well, leading to less durability. Always test your fabric first to confirm proper ink absorption and ideal results.

How Does Curing Time Differ Between Water-Based and Plastisol Inks?

You’ll notice that water-based inks typically have a longer drying time compared to plastisol inks, which dry quickly upon heat. For curing, water-based inks require a lower curing temperature and longer heat exposure to properly set, often around 300°F for 1-2 minutes. Plastisol inks cure faster, usually needing about 350°F for just 30 seconds. This difference impacts your production speed and equipment settings.

Are Water-Based Inks More Environmentally Friendly Than Plastisol?

Water-based inks are more eco-friendly than plastisol because they have a better environmental profile. Their eco-friendly benefits stem from their water-based chemical composition, which reduces the release of harmful chemicals during printing and disposal. Plastisol inks contain PVC and plasticizers that can be toxic and persist in the environment. Choosing water-based inks helps lower your ecological footprint and promotes safer, cleaner printing practices.

What Are the Cost Differences Between Water-Based and Plastisol Inks?

You’ll find that water-based inks generally have a higher initial ink pricing compared to plastisol, making the cost comparison seem steeper upfront. However, water-based inks often cost less in the long run due to reduced disposal and cleanup expenses. While plastisol might seem cheaper initially, consider the total cost of ownership, including environmental impact and labor. Ultimately, your choice depends on your budget and production priorities.

How Do Wash Durability and Longevity Compare for Both Ink Types?

You’ll notice that plastisol inks generally offer better wash durability and longevity, providing superior color retention and wear resistance over time. Water-based inks tend to fade faster and may crack or peel after multiple washes, especially on garments with high wear. If you want your print to stay vibrant and intact longer, plastisol’s durability makes it the better choice, though water-based inks offer eco-friendly benefits.

Conclusion

Choosing between water-based and plastisol inks is like picking between a trusty bicycle and a powerful motorcycle—you need to contemplate your ride. I once started with water-based ink, feeling like I was pedaling uphill, but the vibrant colors and eco-friendly vibe kept me going. Ultimately, understanding your project’s needs will steer you right. Remember, the right ink can turn your printing journey from a bumpy ride into a smooth cruise.