When comparing gel medium and Lazertran for photo transfers, you’ll find that gel transfer is easier and more affordable but produces softer images with less detail, best suited for textured surfaces. Lazertran offers crisper, more precise results and better durability on smooth surfaces, though it involves more advanced techniques and higher costs. To choose the best method for your project and learn helpful tips, explore further insights below.

Key Takeaways

- Gel medium transfer is easier and more affordable but produces softer images with less detail compared to the crisper, high-resolution results of Lazertran.

- Lazertran offers better color accuracy and fine detail preservation, ideal for intricate designs, while gel medium excels on textured or porous surfaces.

- Gel transfers are generally less durable and UV-sensitive, whereas Lazertran provides longer-lasting, more weather-resistant images.

- Gel medium methods require careful surface preparation and sealing, while Lazertran involves specialized paper handling and application techniques.

- Consider project needs, surface type, and durability when choosing between the cost-effective gel medium and the high-quality but more complex Lazertran transfer.

Understanding the Basic Principles of Gel Medium Transfers

Gel medium transfers rely on the adhesive properties of gel mediums to lift images from paper onto different surfaces. When you use a gel medium for image transfer, you apply a layer of it over your printed image, pressing it onto your desired surface. As it dries, the gel bonds with the image, creating a strong adhesive connection. Once dry, you carefully remove the paper, leaving the image embedded in the gel layer on the surface. This process is called gel medium transfer, and it works because the gel acts as a carrier, pulling the image from the paper and depositing it onto the new surface. Understanding this basic principle helps you control the transfer process and achieve clear, durable results. Additionally, selecting the right type of gel medium can influence the transfer quality and longevity of your finished piece.

Exploring the Process of Lazertran Transfers

To start with Lazertran transfers, you’ll need to prepare your transfer sheet carefully, making certain the design is printed correctly and ready to go. Once you apply the design onto your surface, sealing it properly is essential to prevent smudges and ensure a clean transfer. Following these steps precisely will help you achieve a sharp, professional-looking image. Additionally, understanding the AI integration involved in modern printing techniques can enhance your transfer results by optimizing design placement and quality control. Proper material selection also plays a vital role in ensuring a smooth transfer process and durable final product. Incorporating fraud prevention tools into your workflow can further safeguard your projects from potential errors or tampering, ensuring the integrity of your transfer process.

Preparing the Transfer Sheet

Before you begin the transfer process, it’s essential to prepare your transfer sheet properly. Start with surface preparation by cleaning the page thoroughly to remove dust, oils, and fingerprints, ensuring the surface is smooth and primed for adhesion. Next, focus on adhesive selection; Lazertran transfers typically don’t require additional adhesives, but if needed, choose a compatible, flexible adhesive that won’t distort the transfer. Lightly roughening the sheet with fine sandpaper can improve adhesion, but avoid damaging the surface. Confirm the sheet is flat and free of wrinkles or bubbles, as these can affect the transfer quality. Proper surface preparation and the right adhesive choice are key to achieving a clean, crisp transfer with Lazertran.

Applying and Sealing Design

Have you ever wondered how to guarantee your transferred design stays crisp and vibrant? The key is proper transfer sealing. After applying your Lazertran transfer, let it dry completely before sealing. Use a clear, compatible sealer that works with your transfer material to protect the design and prevent smudging. When choosing a sealer, check adhesive compatibility to ensure it bonds well without damaging the transfer. Lightly brush on multiple thin coats rather than one heavy layer, allowing each coat to dry thoroughly. This creates a durable, sealed surface that preserves detail and color. Proper sealing also enhances adhesion if you’re attaching the transfer to different surfaces. Taking these steps ensures your design remains vibrant and intact over time.

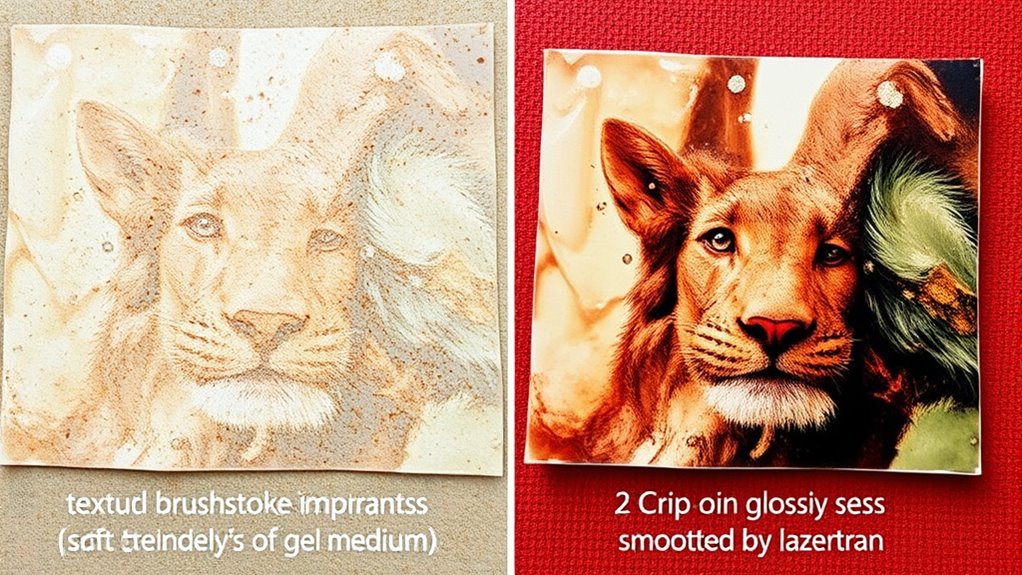

Comparing Image Quality and Detail

When comparing image quality and detail across different photo transfer methods, you’ll notice significant variations in clarity and sharpness. The choice impacts color vibrancy and fine detail, making some methods ideal for certain projects. Here are four key points to consider:

- Gel medium transfers often produce softer images with less sharpness but can enhance color vibrancy with proper sealing. Additionally, the application process can influence the final outcome, requiring careful technique to achieve the desired effect.

- Lazertran tends to deliver crisper details and more accurate color reproduction, especially for intricate designs.

- Fine detail preservation is generally better with Lazertran, making it preferable for detailed artwork. [Understanding the importance of application techniques] is essential to optimize your results.

- Overall sharpness and clarity depend on application technique, but Lazertran usually outperforms gel medium in these areas.

- Proper application techniques are essential to maximize the detail and clarity of your transferred images. Understanding the photo transfer methods helps you select the best approach for your project goals.

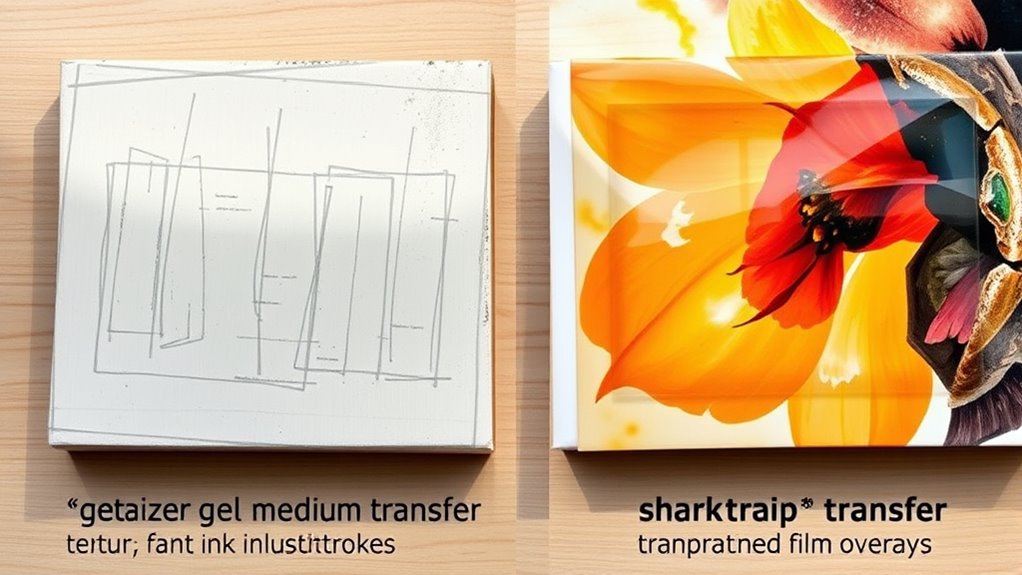

Assessing Compatibility With Different Surfaces

Choosing the right photo transfer method requires considering the surface you plan to apply it on, as compatibility varies considerably. Surface adhesion plays a vital role; some materials, like wood or canvas, offer strong grip, while slick surfaces like glass or metal may need additional preparation. Material flexibility also impacts success—rigid surfaces hold transfers well, but flexible materials like plastic or fabric can cause cracks or peeling if not compatible. Gel medium transfers often work best on porous, textured surfaces because of their excellent adhesion. Lazertran, however, tends to perform better on smooth, non-porous surfaces, provided they allow enough flexibility. Evaluating these factors helps guarantee your transfer not only adheres properly but also remains durable over time. Additionally, understanding the surface properties can inform your choice, ensuring a seamless and lasting transfer. Recognizing how surface compatibility affects adhesion can help you select the most suitable method for your project. Considering the contrast ratio of the transfer surface can also influence how vivid and clear the transferred image appears. Moreover, assessing the surface porosity can determine whether a porous or non-porous transfer method will yield optimal results. Analyzing the surface texture can also help predict how well the transfer will conform and stick without imperfections.

Evaluating Ease of Use and Application Techniques

Evaluating how easy a photo transfer method is to use can save you time and frustration during your project. Consider these key factors:

- Surface preparation – Make sure the surface is smooth, clean, and dry for better transfer adhesion. Proper surface prep is especially important when working with textured or uneven surfaces to ensure a seamless transfer. Using the right materials and tools can further enhance adhesion and reduce errors.

- Application technique – Follow the recommended steps carefully, whether applying gel medium or lasertran transfer. Mastering the specific application process for each method can significantly impact the final outcome.

- Ease of removal – Some methods require gentle scraping or water, affecting application speed. The removal process’s simplicity can influence your overall efficiency and satisfaction with the project.

- Transfer adhesion consistency – A good method provides even adhesion without bubbles or wrinkles. Consistent adhesion is crucial for achieving a professional-looking transfer.

- Understanding automation in business can also help streamline your process, especially in setting up multiple projects efficiently. Implementing efficient techniques can reduce manual effort and improve repeatability.

Both gel medium and lasertran have distinct application techniques, so mastering surface preparation and proper handling ensures a smoother process. Simpler techniques often lead to better transfer adhesion, reducing the need for rework or touch-ups.

Analyzing Durability and Longevity of Results

The durability and longevity of your photo transfer results depend largely on the method you choose and how well you prepare and execute the process. Gel medium transfers typically offer good archival quality when sealed properly, but may be vulnerable to UV resistance issues over time. Lazertran transfers generally provide more durable, UV-resistant results, especially on surfaces exposed to sunlight. To guarantee your transfer lasts, use high-quality, archival materials and protect your work with a UV-resistant coating or sealant. Proper application and curing are essential, regardless of the method, to prevent fading or deterioration. Remember, a well-executed transfer with durable materials will maintain its visual integrity longer, making your project more resilient and lasting over years. Additionally, understanding the importance of vibrational energy and proper sealing techniques can significantly enhance the longevity of your transfer work.

Cost Considerations for Each Method

Cost is a key factor to contemplate when selecting a photo transfer method, as expenses can vary considerably between options. Your decision depends on factors like pricing models and material costs. Here are four key points to consider:

Cost considerations are crucial when choosing a photo transfer method, impacting your project budget and effort.

- Gel medium transfers typically have lower initial material costs but may require more time.

- Lazertran often involves higher upfront expenses due to specialized paper and inks.

- Pricing models differ: gel medium may be a one-time purchase, while Lazertran might involve ongoing costs for supplies.

- Material costs for Lazertran can increase overall expenses, especially if multiple transfers are needed.

- Additionally, considering material longevity can help determine which method better preserves or enhances the transferred image quality over time.

- Being aware of technique effectiveness can guide you toward a method that offers reliable and durable results suited to your project needs.

Balancing these costs helps you choose a method that fits your budget without sacrificing quality or effort.

Limitations and Challenges of Both Transfer Types

You’ll face challenges with transfer durability, as some methods may not last over time or with handling. Material compatibility also limits your options, since not every surface works well with every transfer type. Additionally, mastering the application technique is essential, as improper methods can lead to poor results or damage. For example, understanding air purifier effectiveness can influence the choice of transfer method based on surface and device compatibility.

Transfer Durability Concerns

While both direct and transfer paper methods offer convenient ways to transfer images, they each come with durability concerns that can compromise the longevity of your designs. Fading over time is common, especially with exposure to sunlight or moisture. Surface peeling can also occur if the transfer isn’t properly sealed or applied. To be aware of these issues, consider these points:

- Fading over time reduces image clarity and vibrancy.

- Surface peeling leads to incomplete or damaged designs.

- Adhesion strength varies depending on surface and materials used.

- Environmental factors accelerate deterioration, causing long-term issues.

Understanding these limitations helps you choose the right method and apply proper sealing techniques to improve durability and ensure your artwork lasts.

Material Compatibility Limits

Material compatibility poses significant challenges for both direct and transfer paper methods, as not all surfaces or materials accept transfers equally well. Surface porosity greatly influences ink adhesion; porous surfaces tend to absorb ink, making transfers harder to achieve cleanly. Smooth, non-porous materials often resist ink adhesion, resulting in poor image transfer or incomplete images. For gel medium transfers, porous surfaces may cause uneven adhesion or bleeding, while non-porous surfaces can prevent proper bonding. Similarly, lasertran transfers struggle with incompatible surfaces, leading to smudging or incomplete images. Before starting, you must consider the surface’s porosity and compatibility with your chosen transfer method. Testing small areas helps determine whether the material will accept the transfer without issues, saving time and materials.

Application Technique Challenges

Both direct and transfer paper methods present specific application challenges that can affect the quality of the final image. These include issues with color accuracy and transfer speed, which are vital for a professional finish.

- Uneven application — inconsistent pressure can cause color discrepancies and blurry details.

- Drying time — rushing the process reduces transfer speed but risks smudging or poor adhesion.

- Image distortion — improper handling or stretching affects color fidelity and sharpness.

- Transfer consistency — uneven transfer layers lead to color inaccuracies and patchy areas.

Mastering these challenges involves precise technique, patience, and attention to detail. Both methods demand control over transfer speed and application pressure to achieve accurate colors and crisp images, making the process more reliable and predictable.

Choosing the Right Method for Your Creative Project

How do you choose the right photo transfer method for your creative project? Consider whether you want to incorporate digital printing, which offers sharp details and customization, or prefer techniques like gel medium or Lazertran for a more artistic and textured finish. If your project demands artistic versatility—such as layering, blending, or creating a vintage look—then gel medium transfers might suit you best. Conversely, if you seek precise, high-resolution images with minimal effort, Lazertran could be the better choice. Think about the surface you’re working on, the desired durability, and the overall aesthetic. By weighing these factors, you can select the method that aligns with your vision and technical needs, ensuring your project’s success.

Frequently Asked Questions

Which Transfer Method Is Best for Detailed Photographic Images?

If you want detailed photographic images, consider how each transfer method affects image resolution and color fidelity. Lazertran often preserves fine details and vibrant colors better, making it ideal for high-resolution images. Gel medium transfers can sometimes soften details and alter colors, but they’re easier to work with. For sharp, colorful results, you should choose Lazertran; for a more forgiving process, gel medium might suit your needs.

Can Gel Medium or Lazertran Be Used on Non-Porous Surfaces?

Ever wonder if your transfer tools are versatile enough? You can definitely use gel medium or Lazertran on non-porous surfaces, but surface compatibility varies. Gel medium works best on porous materials, while Lazertran is more adaptable to non-porous surfaces like glass or metal. Material versatility depends on the surface, so choose your method accordingly to achieve the best transfer results without frustration.

Are There Environmental Impacts Associated With Each Transfer Process?

You might wonder about the environmental impact and material sustainability of each transfer process. Gel medium is generally eco-friendlier, as it uses water-based, non-toxic ingredients that are safer for the environment. Lazertran, however, involves chemical solvents that can be more harmful and less sustainable. Choosing a transfer method with lower environmental impact helps you reduce your ecological footprint and promotes sustainable art practices.

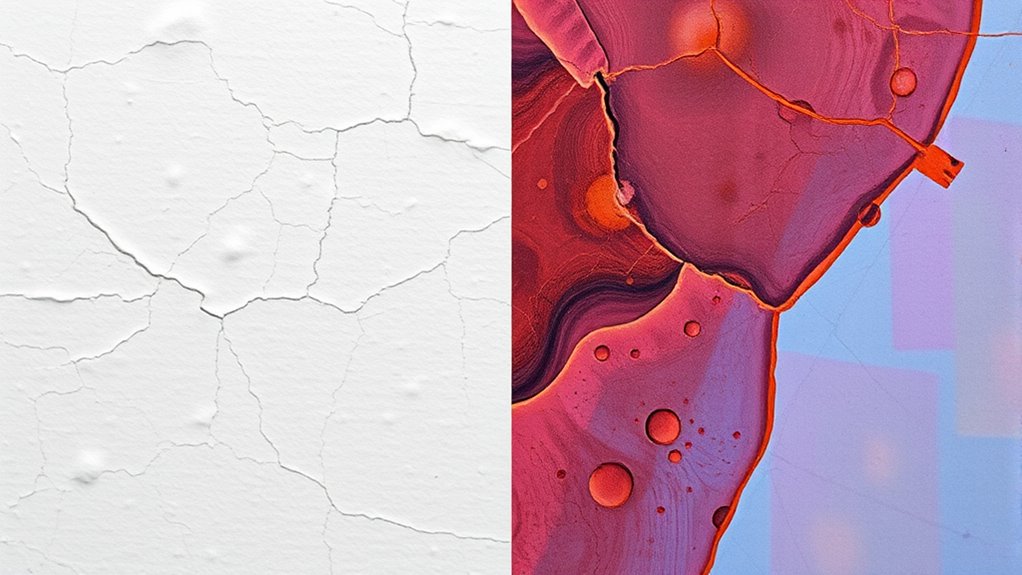

How Do Transfer Methods Affect the Texture of the Final Piece?

You notice that transfer methods influence the surface texture and adhesion qualities of your artwork. Gel mediums often create a matte, slightly textured surface, adding depth, while Lazertran tends to produce a smoother, more glossy finish. The adhesion qualities vary, with gel mediums offering more flexible bonding, whereas Lazertran can provide a crisper image but might be more fragile. Your choice impacts how the final piece feels and looks.

What Safety Precautions Should Be Taken During Each Transfer Technique?

When performing transfer techniques, you should handle chemicals carefully and always wear protective gear like gloves and goggles. Avoid inhaling fumes by working in a well-ventilated area. Read and follow safety instructions on product labels, and keep them out of reach of children. Proper handling minimizes risks, ensuring your safety during the process. Always prioritize safety to prevent accidents or skin irritation.

Conclusion

Choosing between gel medium and Lazertran is like picking the right paintbrush for your masterpiece. Both methods have their quirks and strengths, so consider your surface, detail needs, and durability goals. Think of it as finding the perfect dance partner—each step matters. With a little practice, you’ll master the art of transferring images, turning your projects into stunning works of art. plunge in, experiment, and let your creativity transfer seamlessly!