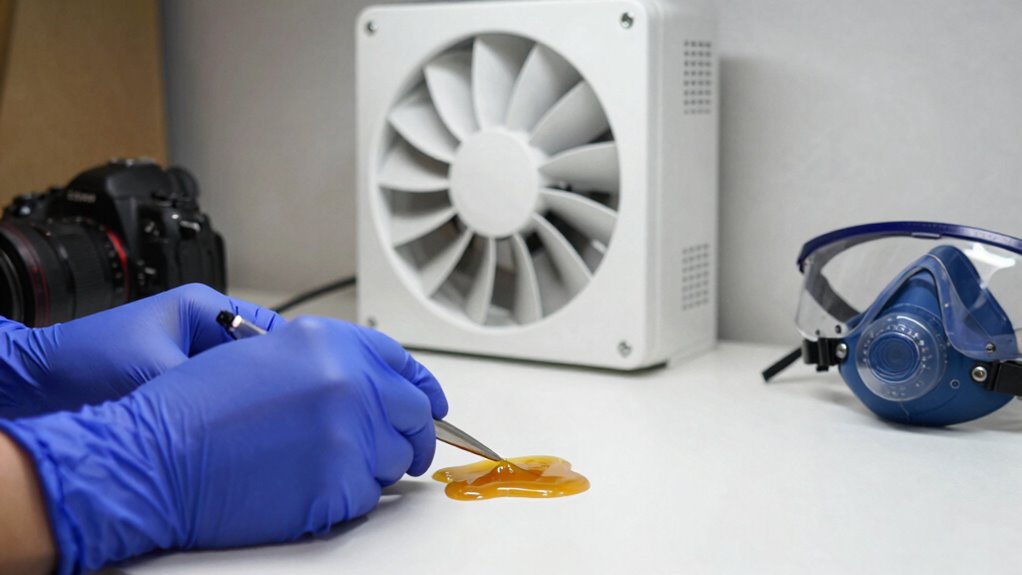

To work safely with resin, proper ventilation is a must. Make certain your workspace has good airflow by using exhaust fans, opening windows, and positioning vents near fumes sources. Always wear suitable gloves made from nitrile, latex, or vinyl to protect your skin. Use a respirator with the right filters during handling or sanding. Avoid common mistakes like neglecting ventilation or improper PPE; staying mindful keeps you safe. Continue exploring to master all essential safety steps.

Key Takeaways

- Ensure proper ventilation with exhaust and intake fans to disperse resin fumes and maintain air quality.

- Recognize hazard signs to identify airborne dangers and implement appropriate protective measures.

- Use correctly fitted nitrile, latex, or vinyl gloves to prevent chemical exposure during resin handling.

- Wear respirators with suitable filters during activities that release fumes, ensuring a proper seal for effective protection.

- Maintain a clean, organized workspace and regularly inspect ventilation and PPE to prevent spills, leaks, and unsafe conditions.

Why Ventilation Is Essential for Resin Safety

Since resin fumes can quickly accumulate and pose health risks, proper ventilation is essential for safety. When working with resin, the release of resin fumes can lead to respiratory irritation and long-term health issues if not managed properly. Ensuring proper airflow helps disperse these fumes, preventing them from building up in your workspace. Without adequate ventilation, resin fumes can linger in the air, increasing your exposure and risking inhalation of harmful chemicals. Good airflow helps to maintain a safer environment by continuously removing airborne contaminants and reducing the concentration of fumes. This not only protects your respiratory health but also minimizes the risk of headaches, dizziness, and other symptoms caused by inhaling resin fumes. Proper ventilation is a simple but critical step in resin safety, and understanding airflow management can further enhance your safety practices. European cloud innovation emphasizes the importance of safe and sustainable practices in various industries, including resin handling. Additionally, implementing ventilation systems designed specifically for resin workspaces can significantly enhance safety and air quality, especially when combined with proper protective equipment. Improving air quality control measures is essential for maintaining a healthy workspace and reducing health risks associated with resin fumes.

How to Set Up Proper Ventilation in Your Resin Workspace

Setting up proper ventilation is key to keeping your workspace safe when working with resin. You need to choose the right ventilation system, position it correctly, and regularly verify that airflow is effective. These steps ensure harmful fumes are effectively removed and air quality stays safe. Incorporating airflow management techniques can further optimize your setup for maximum safety and efficiency. To maintain a safe environment, it’s also important to understand proper airflow patterns and how they influence overall ventilation effectiveness. Ensuring ventilation system maintenance is regularly performed helps sustain consistent air quality and reduces the risk of fumes accumulating in the workspace. Understanding wall surface finishes can also play a role in improving air circulation by reducing surface contamination and facilitating cleaner airflow. Additionally, evaluating air exchange rates ensures your ventilation setup remains capable of handling resin fumes under varying work conditions.

Choose Proper Ventilation System

To guarantee your workspace remains safe when working with resin, setting up an effective ventilation system is essential. You need a system that promotes proper air exchange, removing fumes and volatile organic compounds (VOCs) efficiently. Choose a ventilation setup that includes reliable air filtration to capture airborne particles and contaminants. Consider installing an exhaust fan that vents directly outside, ensuring toxic fumes don’t circulate back into your workspace. Supplement this with an intake fan to bring in fresh air, maintaining a steady flow. Regularly maintain and replace filters to keep air quality high. This combination ensures toxic vapors are minimized, making your workspace safer and compliant with health standards. Proper ventilation setup is your first line of defense against resin fumes. Incorporating proper airflow dynamics can significantly enhance the effectiveness of your ventilation system, ensuring consistent removal of hazardous fumes.

Position Ventilation Correctly

Proper placement of your ventilation system can make a significant difference in keeping your workspace safe. Focus on airflow design to guarantee contaminants are efficiently drawn away from your work area. Position the ventilation intake close to the source of resin fumes, ideally at or slightly below the work surface, to capture fumes at their origin. The exhaust should direct contaminated air outdoors or into a filtration system, preventing buildup. Avoid placing vents near open windows or areas with cross drafts, which can disrupt airflow and reduce effectiveness. Proper ventilation placement ensures a steady, directed airflow that quickly removes hazardous fumes, minimizing health risks. By designing your airflow correctly, you create a safer environment that protects you during resin work.

Maintain Regular Airflow Checks

Regular airflow checks are essential to guarantee your ventilation system continues to operate effectively. You should regularly monitor airflow maintenance to ensure it’s consistent and strong enough to remove fumes. Inspect your filters frequently—look for dust buildup, damage, or clogs that could hinder airflow. Replace or clean filters as needed to maintain peak performance. Check your ventilation fans and ducts for obstructions or leaks that could compromise safety. By staying proactive with filter inspection and airflow assessments, you prevent hazardous fumes from accumulating. Consistent airflow checks help you identify issues early, ensuring your workspace remains safe and compliant with safety standards. Keep a schedule for these inspections so airflow remains reliable and your resin workspace stays well-ventilated. Incorporating Free Floating principles can help optimize your workspace layout for better airflow circulation.

Choosing the Right Gloves for Resin Handling

Choosing the right gloves for resin handling is essential to protect your skin from potential irritation and chemical exposure. The right glove materials, like nitrile or latex, provide chemical resistance and durability. Ensure a proper glove fit—loose gloves can cause accidents, while tight gloves limit dexterity. Consider the specific resin you’re working with, as some require more resistant materials. The table below highlights key factors:

| Glove Material | Key Benefit | Best Use Case |

|---|---|---|

| Nitrile | Chemical resistance, durability | Most resins and chemicals |

| Latex | Flexibility, comfort | Light handling, sensitive skin |

| Vinyl | Cost-effective, basic protection | Short-term or light tasks |

| Neoprene | Oil and chemical resistance | Heavy-duty resin work |

| Butyl | Gas and solvent resistance | Special chemical environments |

Choosing the right gloves involves balancing material strength with comfort for safe, effective resin handling. Material compatibility is crucial to ensure the gloves you select will withstand the specific chemicals involved. Additionally, selecting gloves with appropriate chemical resistance is vital for safety in diverse resin handling scenarios.

When and How to Use Respirators to Protect Your Lungs

You need to recognize signs of resin fumes and airborne particles to know when respirators are necessary. Choosing the right respirator depends on the hazards you face, so it’s essential to select one that provides adequate protection. Always follow proper usage guidelines to guarantee your lungs stay safe during resin work. Being aware of portable power options can help ensure your workspace remains well-ventilated and safe. Incorporating ventilation considerations into your setup can significantly reduce airborne hazards and improve overall safety during resin projects. Additionally, understanding air quality standards can inform safer investment practices outside of your workspace. Proper respirator maintenance is also crucial to ensure continued effectiveness in filtering harmful particles.

Recognize Hazard Signs

Recognizing hazard signs is essential for knowing when to use a respirator to protect your lungs. These hazard signs and safety symbols alert you to airborne dangers like fumes or dust. Pay attention to labels and warnings around your workspace. For example, the table below illustrates common hazard signs you might encounter:

| Sign Type | Description | Action Needed |

|---|---|---|

| Skull & Crossbones | Toxic or deadly chemicals | Wear a respirator |

| Flame | Flammable substances | Use proper ventilation |

| Gas Cylinder | Compressed gas release | Avoid inhalation |

| Exclamation Mark | General hazard or irritant | Use respiratory protection |

| Biohazard | Biological risk | Follow safety protocols |

Always stay alert for these safety symbols—they guide your response and ensure proper respiratory protection. Additionally, understanding the hazard signs can help prevent exposure to dangerous substances during activities like water park maintenance or aquatic exercise setups.

Choose Proper Respirators

Selecting the right respirator is essential for effectively protecting your lungs from airborne hazards. To ensure proper protection, focus on these key steps:

- Respirator fit: Make sure it fits snugly without gaps, providing a secure seal around your face.

- Filter selection: Choose filters rated for resin fumes and particulates to maximize filtration efficiency.

- Proper sizing: Select a respirator size that comfortably fits your face, avoiding discomfort or leaks.

- Check seals and straps: Regularly verify that straps are secure and seals are tight before each use.

- Environmental considerations: Be aware of air quality and ventilation conditions in your workspace to further safeguard your lungs. Proper ventilation can significantly reduce airborne resin particles, enhancing respiratory safety, and following manufacturer instructions for respirator maintenance ensures continued effectiveness. Additionally, monitoring filter indicators when available can help you determine when replacements are needed to maintain optimal protection.

Follow Usage Guidelines

Knowing when and how to use your respirator is essential for effective lung protection during resin work. You should wear it whenever you’re handling uncured resin or during the curing process, when chemical reactions release harmful fumes. Proper usage guarantees your lungs stay safe from airborne particles and vapors. Always follow manufacturer instructions for fitting and filter replacement. To visualize, consider this table:

| Situation | Respirator Use |

|---|---|

| Handling uncured resin | Always wear a properly fitted respirator |

| Resin curing process | Wear during the entire curing phase |

| Mixing resin | Use a respirator to avoid fumes |

| Sanding cured resin | Wear a suitable mask |

| Cleaning tools containing resin | Always protect your lungs |

Following these guidelines minimizes inhalation risks during resin curing and chemical reactions. Proper ventilation also plays a crucial role in reducing airborne resin fumes and enhancing safety during your projects. Additionally, understanding airborne particles helps you better appreciate the importance of using appropriate protective equipment.

Common Mistakes That Jeopardize Resin Safety and How to Avoid Them

One of the most common mistakes that can jeopardize resin safety is neglecting proper preparation and handling procedures. Failing to follow correct protocols increases the risk of chemical spills and unsafe storage. To avoid this, make sure you:

Neglecting proper resin handling and storage risks spills and unsafe conditions.

- Store resins and hardeners in clearly labeled, airtight containers, following strict storage precautions.

- Keep work areas clean and organized to prevent accidental spills.

- Always wear proper gloves and ventilation to minimize exposure.

- Handle chemicals carefully, avoiding rushed or careless movements that could cause leaks or spills. Proper handling techniques are essential for maintaining safety.

- Regularly monitor air quality in your workspace to detect any airborne resin particles or fumes that could pose health risks.

Neglecting these steps can lead to hazardous chemical spills or improper storage, which compromise safety. Staying vigilant with handling and storage precautions is essential for a safe resin workspace.

Budget-Friendly Tips for Working in a Well-Ventilated Space

Creating a safe resin workspace doesn’t have to be expensive; proper ventilation is a key factor that can often be achieved on a budget. To dispel ventilation myths, consider using exhaust fans or opening windows during work. These simple steps improve airflow without costly upgrades. Be aware of glove myths: some believe gloves alone protect you, but proper ventilation is essential to reduce airborne fumes. Here’s a quick comparison:

| Tip | Benefit |

|---|---|

| Use box fans or exhaust fans | Increases air circulation efficiently |

| Open windows regularly | Provides fresh air and removes fumes |

| Avoid relying solely on glove myths | Ensures overall safety from airborne particles |

| Keep workspace clutter-free | Maintains unobstructed airflow |

These tips help you create a safer environment without breaking the bank.

Additional Safety Gear and Practices for Resin Crafters

To protect yourself effectively while working with resin, investing in the right safety gear is essential. Beyond gloves and ventilation, consider these additional practices:

- Wear a respirator mask to prevent inhaling fumes during resin mixing and curing.

- Use chemical-resistant aprons and eye protection to avoid skin and eye contact.

- Keep a spill kit nearby to manage resin spills quickly, reducing exposure risks.

- Know your emergency procedures, including proper resin disposal methods and first aid steps for skin contact or inhalation.

Proper resin disposal prevents environmental harm, while understanding emergency procedures guarantees your safety in unexpected situations. Incorporate these safety gear and practices into your routine to minimize risks and work confidently with resin.

Frequently Asked Questions

How Often Should I Replace or Clean My Resin Ventilation Filters?

You should replace or clean your resin ventilation filters regularly, ideally every 1 to 3 months, depending on usage and filter type. Regular filter maintenance guarantees peak ventilation lifespan and keeps airborne resin fumes in check. Check your filters frequently—if they look dirty or clogged, replace them sooner. Maintaining clean filters not only improves safety but also prolongs your ventilation system’s effectiveness, protecting your health during resin work.

Are There Specific Gloves Recommended for Long-Term Resin Handling?

Did you know prolonged resin exposure can cause skin irritations? For long-term handling, you should choose gloves made from nitrile or neoprene, which resist chemicals effectively. Opt for a glove thickness of at least 4 mil to guarantee durability and protection. These materials and thicknesses provide a reliable barrier, so your skin stays safe during extended resin work. Always prioritize quality gloves to minimize health risks.

Can DIY Ventilation Setups Effectively Protect Against Resin Fumes?

DIY ventilation setups can help with resin fume mitigation, but they might not fully safeguard you. Proper airflow, like exhaust fans and vent hoods, can reduce fumes, but they often aren’t as reliable or effective as professional systems. You should always prioritize using well-designed, high-quality ventilation and wear gloves to ensure your safety. Relying solely on DIY solutions could leave you exposed to harmful fumes.

What Signs Indicate My Resin Workspace Lacks Proper Ventilation?

Imagine your workspace as a fishbowl—if you notice a persistent odor, it’s like the water’s becoming murky, signaling poor air quality. You might also feel a constant, irritating smell or experience difficulty breathing, which indicates your ventilation isn’t clearing fumes effectively. If these signs occur, your workspace lacks proper airflow, and you should enhance ventilation immediately to protect your health and ensure safe resin handling.

Are There Legal or Safety Regulations I Should Be Aware of for Resin Work?

You need to prioritize legal compliance and safety standards when working with resin. Make sure you follow OSHA regulations and local laws regarding chemical handling, ventilation, and protective gear. Keep updated on safety standards from organizations like OSHA or the CDC. Not adhering to these regulations can lead to health risks and legal consequences. Always stay informed, use proper ventilation, gloves, and protective equipment to guarantee a safe workspace.

Conclusion

Did you know that proper ventilation can reduce resin-related health risks by up to 80%? By prioritizing good airflow, wearing the right gloves, and using respirators when needed, you’re markedly lowering your exposure to harmful fumes and chemicals. Remember, 1 in 4 resin crafters experience respiratory issues without these precautions. Stay vigilant, implement these safety tips, and enjoy your creative projects without compromising your health. Your safety always comes first!