If you’re looking for the 15 best bottle labeler machines for 2026, I’ve found options that range from compact manual models like the Sumeve and ZonePack to semi-automatic units such as VEVOR and Zyphor. High-speed industrial systems like the MT-30 are also included for larger volumes. Each offers features suited to different bottle shapes, labels, and industries. Keep exploring to find the perfect match for your production needs and goals.

Key Takeaways

- Top models include semi-automatic, manual, and high-speed labelers tailored for various industries and bottle shapes.

- Features like optical sensors, adjustable rollers, and waterproof labels enhance efficiency and precision.

- Durable construction with materials such as aluminum alloys and stainless steel ensures longevity and easy maintenance.

- Industry-specific options support food, beverage, cosmetics, pharmaceuticals, and craft businesses.

- Consider factors like speed, compatibility, automation features, and budget when selecting the best labeler for 2026.

| VEVOR Semi-Automatic Round Bottle Labeler |  | Best Semi-Auto | Operation Mode: Semi-automatic | Bottle Size Range: 0.78-4.72 in (20-120 mm) | Label Width Capacity: 0.51-5.9 in (13-150 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| VEVOR Manual Round Labeling Machine (15-20 pcs/min) |  | Best Manual | Operation Mode: Manual | Bottle Size Range: 0.78-4.72 in (20-120 mm) | Label Width Capacity: 0.39-5.12 in (10-130 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| Zyphor Semi-Automatic Bottle Labeling Machine |  | Most Precise | Operation Mode: Semi-automatic | Bottle Size Range: 0.47-5.9 in (12–150 mm) | Label Width Capacity: 0.4-5.9 in (10-150 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| Sumeve Manual Round Bottle Labeling Machine |  | Budget Choice | Operation Mode: Manual | Bottle Size Range: 0.6-4 cm (approx. 0.24-1.57 in) | Label Width Capacity: 1-5.1 cm (approx. 0.39-2 in) | VIEW LATEST PRICE | See Our Full Breakdown |

| Phomemo D30 Bluetooth Label Maker Printer |  | Portable Favorite | Operation Mode: Bluetooth thermal printer (print-only, no automatic/ manual operation) | Bottle Size Range: 0.75-2 in (19-50 mm) | Label Width Capacity: Up to 2.2 in (55 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| Hanchen Manual Bottle Labeling Machine with Handle |  | High Efficiency | Operation Mode: Manual | Bottle Size Range: 0.59-4.72 in (15-120 mm) | Label Width Capacity: 0.5-5.9 in (12-150 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| Sumeve Manual Bottle Labeling Machine |  | User-Friendly | Operation Mode: Manual | Bottle Size Range: 0.6-4 in (15-100 mm) | Label Width Capacity: 10-110 mm (0.39-4.33 in) | VIEW LATEST PRICE | See Our Full Breakdown |

| BbqLiaxon Semi-Automatic Square Bottle Labeler |  | Industrial Strength | Operation Mode: Semi-automatic | Bottle Size Range: Suitable for square bottles, flat surfaces, no specific size range | Label Width Capacity: 0.7-4.5 in (18-114 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| SUPVAN T50M Pro Bluetooth Label Maker with Tape |  | Tech-Enabled | Operation Mode: Bluetooth print device (print-only, no automatic/manual) | Bottle Size Range: 0.75-2 in (19-50 mm) | Label Width Capacity: Up to 2 in (50 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| ZonePack Manual Bottle Labeling Machine with Handle |  | Space Saver | Operation Mode: Manual | Bottle Size Range: 0.79-4.72 in (2-12 cm) | Label Width Capacity: 10-110 mm (0.39-4.33 in) | VIEW LATEST PRICE | See Our Full Breakdown |

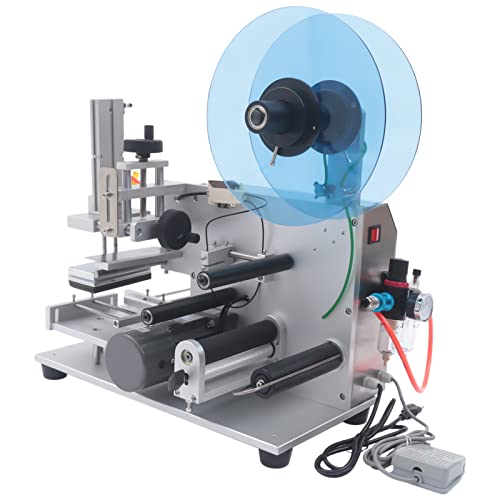

| TAL-2100ER Electric Bottle Label Applicator |  | Easy Operation | Operation Mode: Electric, manual activation via footswitch | Bottle Size Range: 0.79-4.72 in (2-12 cm) | Label Width Capacity: 10-110 mm (0.39-4.33 in) | VIEW LATEST PRICE | See Our Full Breakdown |

| Hanchen Semi-Automatic Cylinder Bottle Labeler |  | High Accuracy | Operation Mode: Semi-automatic | Bottle Size Range: φ0.6-4.7 in (15-120 mm) | Label Width Capacity: 0.5-5.9 in (12-150 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| ZONEPACK Manual Wine Bottle Labeling Machine |  | Manual Precision | Operation Mode: Manual | Bottle Size Range: 15-120 mm (0.59-4.72 in) | Label Width Capacity: 0.39-6.29 in (10-160 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

| TozMvi Semi-Automatic Bottle Labeling Machine |  | Heavy-Duty | Operation Mode: Semi-automatic | Bottle Size Range: Suitable for bottles with diameters 20-80 mm | Label Width Capacity: 10-110 mm (0.39-4.33 in) | VIEW LATEST PRICE | See Our Full Breakdown |

| MT-30 Manual Bottle Labeling Machine with Handle |  | Best for Small Batches | Operation Mode: Manual | Bottle Size Range: 0.79-4.72 in (2-12 cm) | Label Width Capacity: 0.39-4.72 in (10-120 mm) | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

VEVOR Semi-Automatic Round Bottle Labeler

If you’re looking for a reliable and efficient labeling solution for round bottles, the VEVOR Semi-Automatic Round Bottle Labeler is an excellent choice. I find its ability to handle 20-50 bottles per minute impressive, especially for various industries like food, beverage, and cosmetics. Its durable aluminum alloy construction ensures long-lasting performance, while the adjustable label positioning guarantees a perfect fit without wrinkles or bubbles. The fiber optic sensor provides precise detection, making labeling accurate and smooth. Plus, the manual twist adjustment makes swapping labels quick and easy. Overall, it’s a smart, semi-automatic option for those needing high-quality, consistent labeling.

- Operation Mode:Semi-automatic

- Bottle Size Range:0.78-4.72 in (20-120 mm)

- Label Width Capacity:0.51-5.9 in (13-150 mm)

- Material Construction:Aluminum alloy

- Power Source:Electric (semi-automatic)

- Labeling Speed / Capacity:20-50 bottles/min

- Additional Feature:Fiber optic sensor accuracy

- Additional Feature:Manual twist label adjustment

- Additional Feature:Supports high-resolution labels

VEVOR Manual Round Labeling Machine (15-20 pcs/min)

The VEVOR Manual Round Labeling Machine is an excellent choice for small to medium-scale producers seeking reliable, efficient labeling without the complexity of electric models. It labels 15-20 bottles per minute with simple manual operation, reducing errors and increasing productivity. Its adjustable design fits round bottles from 0.78 to 4.72 inches in diameter and works with transparent or adhesive labels up to 5.12 inches wide. Made from durable stainless steel and featuring a rust-resistant roller shaft, it’s built for longevity. The upgraded manual adjustment system allows quick label changes, while the ergonomic hand-crank ensures ease of use. It’s perfect for continuous, hassle-free labeling in various industries.

- Operation Mode:Manual

- Bottle Size Range:0.78-4.72 in (20-120 mm)

- Label Width Capacity:0.39-5.12 in (10-130 mm)

- Material Construction:Steel, SUS201, PC

- Power Source:Manual

- Labeling Speed / Capacity:15-20 bottles/min

- Additional Feature:Ergonomic hand-crank handle

- Additional Feature:Compatibility with transparent labels

- Additional Feature:Durable SUS201 roller shaft

Zyphor Semi-Automatic Bottle Labeling Machine

Designed for small and medium businesses, the Zyphor Semi-Automatic Bottle Labeling Machine stands out with its high labeling speed of 20–50 bottles per minute, making it an excellent choice for those seeking efficiency without sacrificing precision. It uses advanced optical eye sensors to guarantee accurate label placement, reducing waste and errors. Compatible with bottles ranging from 0.47 to 5.9 inches in diameter and label lengths from 0.4 to 11.8 inches, it works well with transparent labels too. Built from durable stainless steel and aluminum, it’s easy to set up, adjust, and maintain, making it ideal for various cylindrical bottles in different industries.

- Operation Mode:Semi-automatic

- Bottle Size Range:0.47-5.9 in (12–150 mm)

- Label Width Capacity:0.4-5.9 in (10-150 mm)

- Material Construction:Stainless steel, aluminum alloy

- Power Source:Manual

- Labeling Speed / Capacity:20-50 bottles/min

- Additional Feature:Optical eye sensor system

- Additional Feature:Waste-paper collection wheel

- Additional Feature:Adjustable rollers for various sizes

Sumeve Manual Round Bottle Labeling Machine

For those seeking an affordable, manual solution to label round bottles accurately, the Sumeve Manual Round Bottle Labeling Machine stands out as a practical choice. Designed for glass bottles, cans, and plastics with diameters between 0.6 to 4 cm, it’s easy to use and adjust. Made from durable all-metal, it offers long-lasting performance. You simply position the bottle with adjustable rollers and turn the handle to apply labels smoothly, ensuring they’re wrinkle-free and well-aligned. Its versatile design accommodates various label sizes, making it ideal for small-scale or occasional labeling tasks without the need for electricity.

- Operation Mode:Manual

- Bottle Size Range:0.6-4 cm (approx. 0.24-1.57 in)

- Label Width Capacity:1-5.1 cm (approx. 0.39-2 in)

- Material Construction:Metal, all-metal body

- Power Source:Manual

- Labeling Speed / Capacity:15-20 bottles/min

- Additional Feature:Extended label size capacity

- Additional Feature:All-metal durable construction

- Additional Feature:Adjustable bottle positioning

Phomemo D30 Bluetooth Label Maker Printer

If you need a portable and affordable label maker that delivers high-quality prints on the go, the Phomemo D30 Bluetooth Label Maker Printer is an excellent choice. It’s compact, lightweight (just 5.6 ounces), and features a rechargeable battery, making it perfect for home, school, or small business use. It supports continuous and fixed-length labels up to 0.55 inches wide, with faster, clearer printing thanks to its upgraded German thermal print head. Compatible with Android and iOS devices via Bluetooth 4.0, it offers a versatile companion app with over 1,000 symbols, decorative frames, fonts, barcode, QR code, and image options—ideal for organizing, labeling, and creative projects wherever you are.

- Operation Mode:Bluetooth thermal printer (print-only, no automatic/ manual operation)

- Bottle Size Range:0.75-2 in (19-50 mm)

- Label Width Capacity:Up to 2.2 in (55 mm)

- Material Construction:Plastic, metal components

- Power Source:Battery-powered (Bluetooth printer)

- Labeling Speed / Capacity:Print speed 40 ppm, 1 sheet/sec

- Additional Feature:App with 1000+ symbols

- Additional Feature:Colorful patterned tapes

- Additional Feature:Inkless thermal printing

Hanchen Manual Bottle Labeling Machine with Handle

The Hanchen Manual Bottle Labeling Machine with Handle stands out for its precise, controlled application, making it ideal for small-scale production or craft businesses that need reliable, manual labeling. Its ergonomic press handle ensures smooth, accurate label placement on a variety of bottles and jars, from vials to lipsticks. Adjustable features support cylindrical labels with diameters from 15-120mm, maintaining high accuracy within ±0.5mm. It’s designed for efficiency, capable of labeling up to 40 pieces per minute, with a user-friendly handle that minimizes fatigue. Built with durable materials, it’s easy to install and operate, perfect for boosting productivity in a compact setup.

- Operation Mode:Manual

- Bottle Size Range:0.59-4.72 in (15-120 mm)

- Label Width Capacity:0.5-5.9 in (12-150 mm)

- Material Construction:Metal (mainly aluminum alloy), durable steel

- Power Source:Manual

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:Bright yellow anti-slip finish

- Additional Feature:Quick-release setup

- Additional Feature:Fits multiple bottle diameters

Sumeve Manual Bottle Labeling Machine

Looking for an easy-to-use manual labeler that handles round bottles of various sizes? The Sumeve Manual Bottle Labeling Machine is a versatile choice, compatible with glass, cans, and plastic bottles with diameters from 0.6 to 4 inches. Its adjustable design and extended length accommodate labels 1 to 5.1 inches wide and 1 to 10 inches long. The sturdy metal body and pressing bar ensure precise, bubble-free labels, while simple manual operations make it user-friendly. Weighing about 15.22 pounds, it’s perfect for industrial or scientific settings. Overall, it offers durability, adaptability, and professional results, making labeling quick and efficient.

- Operation Mode:Manual

- Bottle Size Range:0.6-4 in (15-100 mm)

- Label Width Capacity:10-110 mm (0.39-4.33 in)

- Material Construction:Metal (sturdy steel), all-metal body

- Power Source:Manual

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:Large label roll support

- Additional Feature:Precise manual adjustment

- Additional Feature:Suitable for scientific use

BbqLiaxon Semi-Automatic Square Bottle Labeler

For small businesses seeking reliable, precise labeling, the BbqLiaxon Semi-Automatic Square Bottle Labeler stands out with its advanced PLC control and precision sensors, ensuring consistent ±0.039-inch placement accuracy. This guarantees perfectly aligned, bubble-free labels that elevate your product presentation. Built from durable aluminum and iron, it offers long-term reliability and stability during busy operations. Capable of labeling 20-40 bottles per minute, it features a footswitch for hands-free operation, increasing efficiency. Its adjustable head and compatibility with various label sizes make it versatile for different bottle shapes, including wine and cosmetics, making it a great addition to any small-scale production line.

- Operation Mode:Semi-automatic

- Bottle Size Range:Suitable for square bottles, flat surfaces, no specific size range

- Label Width Capacity:0.7-4.5 in (18-114 mm)

- Material Construction:Aluminum, iron, durable base

- Power Source:Semi-automatic

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:PLC control system

- Additional Feature:Overcurrent safety protection

- Additional Feature:Fully adjustable label head

SUPVAN T50M Pro Bluetooth Label Maker with Tape

If you need a versatile label maker that’s perfect for home, office, or small business use, the SUPVAN T50M Pro Bluetooth Label Maker with Tape stands out with its ability to print waterproof labels up to 2 inches wide. It’s compatible with Android and iOS devices, offering a range of label styles including square, round, cable, and file labels. No ink or toner is needed, thanks to its inkless printing technology, and it produces high-resolution labels at 203 dpi. Lightweight at just over 15 ounces, it’s easy to handle and quick to operate, making label creation efficient and hassle-free for various organizational needs.

- Operation Mode:Bluetooth print device (print-only, no automatic/manual)

- Bottle Size Range:0.75-2 in (19-50 mm)

- Label Width Capacity:Up to 2 in (50 mm)

- Material Construction:Plastic, electronic components

- Power Source:Battery-powered Bluetooth printer

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:650+ icon library

- Additional Feature:Automatic label size recognition

- Additional Feature:Supports barcode/QR code

ZonePack Manual Bottle Labeling Machine with Handle

The ZonePack Manual Bottle Labeling Machine with Handle stands out for its ergonomic design and adjustable components, making it ideal for small-scale producers seeking a reliable, space-saving labeling solution. Its upgraded pressing bar guarantees a better fit for labels, while the load-bearing bar minimizes damage during transport. This compact, desktop model operates manually without external power, promoting energy efficiency. It supports bottles from 15-120mm in diameter and up to 150mm in height, with adjustable holders for various sizes. Perfect for round plastic, glass, or metal bottles, it’s a versatile tool for cosmetics, beverages, food, and medical industries.

- Operation Mode:Manual

- Bottle Size Range:0.79-4.72 in (2-12 cm)

- Label Width Capacity:10-110 mm (0.39-4.33 in)

- Material Construction:Metal, durable plastic parts

- Power Source:Manual

- Labeling Speed / Capacity:10-30 bottles/min

- Additional Feature:Compact desktop design

- Additional Feature:Energy-efficient manual operation

- Additional Feature:Adjustable bottle holder

TAL-2100ER Electric Bottle Label Applicator

The TAL-2100ER Electric Bottle Label Applicator stands out for its high-speed and precise labeling functionality, making it an ideal choice for industrial and manufacturing environments where efficiency is key. It handles bottles with diameters from 1 to 5 inches and operates at 15-20 bottles per minute, ensuring quick, accurate application. The user places bottles into the carriage, activates the device with a footswitch, and it wraps labels around the bottles. It primarily works with opaque labels, though transparent labels require an optional Photo Eye. Compact and reliable, the TAL-2100ER is perfect for high-volume labeling tasks in busy production lines.

- Operation Mode:Electric, manual activation via footswitch

- Bottle Size Range:0.79-4.72 in (2-12 cm)

- Label Width Capacity:10-110 mm (0.39-4.33 in)

- Material Construction:Metal, durable construction

- Power Source:Electric, footswitch activation

- Labeling Speed / Capacity:15-20 bottles/min

- Additional Feature:Manual activation footswitch

- Additional Feature:Supports opaque labels

- Additional Feature:Simple control with one processor

Hanchen Semi-Automatic Cylinder Bottle Labeler

Designed for small to medium-sized operations, the Hanchen Semi-Automatic Cylinder Bottle Labeler stands out with its high-precision optical eye sensor technology. It efficiently labels cylindrical bottles with diameters from 0.6 to 4.7 inches and lengths up to 11.8 inches. Made of durable aluminum alloy, it features adjustable rollers, a sturdy swing arm, and automatic optical fiber positioning for easy setup. With a capacity of 20-40 bottles per minute, it minimizes missed labels and waste, boosting productivity. Its compact design allows placement on tables or lines, making it ideal for small enterprises seeking reliable, precise labeling without the complexity of fully automatic systems.

- Operation Mode:Semi-automatic

- Bottle Size Range:φ0.6-4.7 in (15-120 mm)

- Label Width Capacity:0.5-5.9 in (12-150 mm)

- Material Construction:Metal, aluminum alloy

- Power Source:Electric (semi-automatic)

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:Ethernet connectivity option

- Additional Feature:High sensitivity photo eye

- Additional Feature:300 dpi print resolution

ZONEPACK Manual Wine Bottle Labeling Machine

If you’re looking for an easy-to-use labeler suited for small-scale wine production, the ZONEPACK Manual Wine Bottle Labeling Machine stands out. Its compact design and manual operation make it energy-efficient and simple to operate without power. Compatible with round bottles of various sizes, it handles labels up to 6.29 inches wide and 11.81 inches long, fitting bottles with diameters from 15 to 120mm and heights up to 340mm. The adjustable holder and modular design ensure versatility, while the ability to apply transparent stickers adds to its convenience. This machine is perfect for small wineries, craft brewers, or hobbyists needing reliable, cost-effective labeling.

- Operation Mode:Manual

- Bottle Size Range:15-120 mm (0.59-4.72 in)

- Label Width Capacity:0.39-6.29 in (10-160 mm)

- Material Construction:Metal, sturdy base

- Power Source:Manual

- Labeling Speed / Capacity:15-30 bottles/min

- Additional Feature:Modular, easy maintenance

- Additional Feature:Manual energy-saving operation

- Additional Feature:Applies larger labels

TozMvi Semi-Automatic Bottle Labeling Machine

For those seeking efficient and precise labeling on round bottles, the TozMvi Semi-Automatic Bottle Labeling Machine stands out as an ideal choice. It works well with glass, plastic, or metal bottles, supporting diameters from 20 to 80 mm and heights up to 140 mm. With a 36W motor and simple one-touch controls, it speeds through 20–40 bottles per minute. Its optical sensor detects label transparency, reducing errors, while adjustable rods ensure smooth, bubble-free labels. Compact and portable, it’s perfect for small to medium industries in food, pharma, or beverages. Plus, it’s easy to operate and maintain, offering professional results every time.

- Operation Mode:Semi-automatic

- Bottle Size Range:Suitable for bottles with diameters 20-80 mm

- Label Width Capacity:10-110 mm (0.39-4.33 in)

- Material Construction:Metal, plastic parts

- Power Source:Electric (semi-automatic)

- Labeling Speed / Capacity:20-40 bottles/min

- Additional Feature:Automatic optical sensor

- Additional Feature:Adjustable pressing rods

- Additional Feature:Compact portable design

MT-30 Manual Bottle Labeling Machine with Handle

The MT-30 Manual Bottle Labeling Machine with Handle stands out for its high-precision sensor, which guarantees labels are applied accurately within ±0.5mm, making it ideal for users seeking neat and professional results. It’s designed for round bottles with diameters from 0.79 to 4.72 inches, suitable for PET, plastic, glass, and metal containers across cosmetics, beverages, food, and medical industries. The adjustable holder and manual operation make it easy to customize for different bottle sizes. Built from durable iron and equipped with safety features, this machine optimizes workflow, labeling 10-30 bottles per minute, ensuring efficiency and consistent quality.

- Operation Mode:Manual

- Bottle Size Range:0.79-4.72 in (2-12 cm)

- Label Width Capacity:0.39-4.72 in (10-120 mm)

- Material Construction:Metal, high-quality iron

- Power Source:Manual

- Labeling Speed / Capacity:10-30 bottles/min

- Additional Feature:Over-current protection

- Additional Feature:High-precision sensor

- Additional Feature:Wide bottle size range

Factors to Consider When Choosing a Bottle Labeler Machine

When choosing a bottle labeler, I consider factors like compatibility with my bottle sizes and shapes, as well as the labeling speed I need. I also weigh the benefits of manual versus automatic models, durability, and how easy the machine is to operate. These points help me find a machine that fits my production requirements and budget perfectly.

Bottle Compatibility Requirements

Choosing a bottle labeler machine requires careful attention to bottle compatibility to guarantee smooth operation and accurate labeling. First, verify the machine supports your bottle’s diameter, typically from 0.6 inches to over 5 inches. It should also accommodate your bottles’ height and circumference for precise label placement. If you use different shapes—cylindrical, square, or irregular—confirm the machine can handle these variations. Compatibility with your label roll size, including core diameter and roll-out diameter, is essential to avoid supply issues. Additionally, look for adjustable features that let you set the machine to fit various bottle sizes securely. Proper compatibility ensures efficient labeling, reduces downtime, and minimizes errors, making your investment worthwhile.

Labeling Speed Options

Labeling speed is a crucial factor because it directly impacts your production efficiency. I recommend choosing a machine that matches your line’s throughput to prevent bottlenecks. Speeds range from about 10 to 50 bottles per minute, depending on automation and design. Semi-automatic models typically label 15 to 40 bottles per minute, but they require manual intervention, which can slow overall output. Fully automatic labelers can exceed 50 bottles per minute, ideal for high-volume production. Keep in mind that bottle size, shape, and label type also influence achievable speeds. If your operation demands quick turnaround, investing in a faster, fully automatic machine makes sense. Conversely, smaller batches or more flexibility might be better suited to semi-automatic options. Matching speed with your production needs is key to maximizing efficiency.

Manual Vs Automatic Models

Deciding between manual and automatic bottle labelers hinges on several important factors. Manual models require human operation, giving you more control but at a slower pace—typically 10 to 30 bottles per minute. They’re more affordable upfront and easier to maintain, making them suitable for small-scale or occasional labeling. Automatic machines, on the other hand, use motorized parts and sensors to apply labels more quickly—20 to 50 bottles per minute—reducing labor costs and increasing efficiency. They often feature advanced detection and precise positioning technology for consistent results. Your choice depends on your production volume, budget, and efficiency needs. Manual models suit startups or low-volume runs, while automatic systems are ideal for larger-scale manufacturing demanding speed and precision.

Durability and Material

The durability of a bottle labeler largely depends on the materials used in its construction. High-quality materials like stainless steel, aluminum alloys, or heavy-duty plastics ensure the machine can withstand frequent use and tough environments. These materials resist corrosion, rust, and wear, which is essential for maintaining performance over time. In industries like food, beverages, and pharmaceuticals, resistance to chemicals, water, and cleaning agents is critical. Heavier, sturdier materials boost stability during operation, reducing vibrations and improving label accuracy. Impact-resistant components help minimize damage from accidental drops or bumps, extending the machine’s lifespan. Overall, selecting a labeler built from durable, high-grade materials guarantees long-term reliability and reduces maintenance costs, making it a smart investment for any production line.

Ease of Operation

Choosing a bottle labeler that’s easy to operate can substantially boost efficiency and reduce training time. Look for machines with user-friendly controls like simple buttons, manual handles, or automatic sensors that make labeling straightforward. Adjustable components and clear instructions help decrease setup time and minimize operator errors. Semi-automatic models are particularly helpful, as they combine manual adjustments with automatic features, requiring less technical knowledge than fully automatic systems. Optical sensors or fiber optic detection simplify label alignment by automatically identifying label positions, reducing manual corrections. Ergonomic design elements, such as comfortable handles and accessible controls, make operation more comfortable and efficient. Overall, selecting a machine with intuitive controls and adaptable features guarantees smoother operation, saving time and effort in your labeling process.

Industry Specific Features

When selecting a bottle labeler, it’s vital to consider industry-specific features that guarantee the machine fits your unique production needs. Different industries demand tailored capabilities; for example, pharmaceuticals and cosmetics require high-precision sensors and bubble-free application to meet safety and quality standards. Food and beverage labelers must handle waterproof, oil-resistant labels and withstand temperature variations and moisture. Conversely, industries like wine and spirits often prefer semi-automatic or manual labelers for greater flexibility with complex or unique bottle shapes. Compatibility with various label types—such as transparent, textured, or large-format labels—is also indispensable for maintaining branding consistency. Recognizing these industry-specific requirements helps you select a labeler that assures optimal performance and compliance.

Cost and Maintenance

Selecting a bottle labeler machine involves carefully weighing both upfront costs and ongoing maintenance expenses to guarantee it fits within your budget and production goals. I consider the initial purchase price relative to my operational needs, ensuring it offers good value without overspending. I also evaluate the machine’s maintenance requirements, such as parts replacement, cleaning, and calibration, to keep long-term costs manageable. Choosing models with easily accessible and replaceable parts minimizes downtime and maintenance expenses. I look for machines with automated features that reduce labor and decrease maintenance frequency. Additionally, I check the manufacturer’s warranty and customer support, as reliable service can lower repair costs and simplify maintenance. Balancing these factors helps me select a cost-effective, durable labeler suited for sustained production.

Frequently Asked Questions

What Is the Maximum Bottle Size Compatible With These Labelers?

The maximum bottle size compatible with these labelers varies depending on the model, but generally, they can handle bottles up to 12 inches in height and 4 inches in diameter. I recommend checking the specific machine’s specifications before purchasing. Most high-end labelers are adjustable, so they can accommodate a wide range of bottle sizes, making them versatile for different packaging needs.

How Easy Is the Machine to Operate for Beginners?

I find that most bottle labeler machines are quite beginner-friendly. They typically feature intuitive controls, step-by-step instructions, and straightforward setup processes. I’ve seen new users get up and running quickly, especially with machines that have digital displays or automated features. While some models might require a bit of initial practice, overall, I’d say these machines are designed to be accessible, making labeling simple even for first-time users.

Can These Machines Handle High-Volume Labeling Tasks?

Absolutely, these machines are built for high-volume tasks. I’ve used them in busy production lines, and they handle large quantities without breaking a sweat. Their speed and efficiency mean I can label thousands of bottles quickly, maintaining consistency and quality. If you’re looking for reliable, high-capacity labeling, these machines will definitely meet your needs, making your workflow smoother and more productive.

What Maintenance Is Required for Optimal Performance?

Maintaining your labeler is like tending a garden; consistent care keeps everything thriving. I regularly clean the rollers and sensors, lubricate moving parts, and check for wear and tear. I also guarantee the software is updated and calibrate the system as needed. Doing these simple steps prevents breakdowns and keeps the machine running smoothly, so you can focus on your production without interruptions.

Are There Customizable Options for Different Label Shapes and Sizes?

Yes, most bottle labeler machines offer customizable options for different label shapes and sizes. I find that adjustable guides, interchangeable label heads, and customizable software settings make it easy to switch between various formats. This flexibility allows me to efficiently handle diverse packaging needs without investing in multiple machines. If you’re considering a labeler, look for models that emphasize versatility and easy customization to suit your specific labeling requirements.

Conclusion

Choosing the right bottle labeler machine really comes down to understanding your needs and budget. With so many options out there, it’s easy to get overwhelmed, but remember, the right tool can make all the difference in the world. Don’t put all your eggs in one basket—take your time, weigh your options, and pick the machine that’ll work best for you. After all, a good fit is worth its weight in gold!