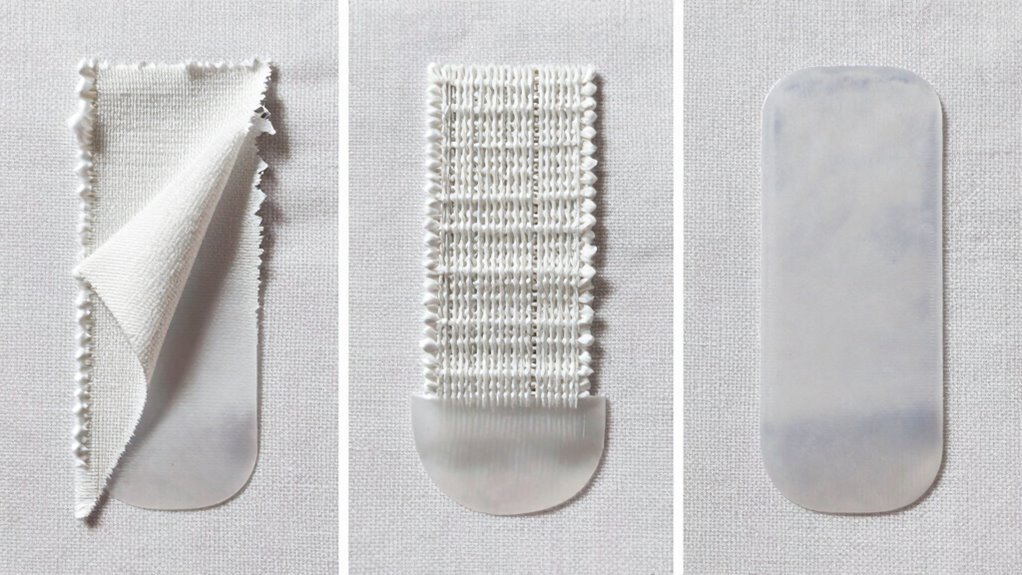

Choosing the right embroidery stabilizer depends on your fabric and design. Tear-away stabilizers are great for lightweight fabrics and simple stitches because they’re easy to remove afterward. Cut-away stabilizers offer long-lasting support for stretchy or delicate fabrics with detailed designs. Wash-away stabilizers are perfect for soft, intricate embroidery on delicate fabrics, as they rinse away easily. Knowing when to use each type helps you achieve professional results—stay with us to learn more.

Key Takeaways

- Tear-away stabilizers are ideal for stable fabrics and small, detailed designs, easily removed post-embroidery.

- Cut-away stabilizers provide permanent support, perfect for stretchy or delicate fabrics needing long-lasting stability.

- Wash-away stabilizers are lightweight, designed for delicate projects, and are rinsed out after stitching for a soft finish.

- Selection depends on fabric type, design complexity, and desired finish, with tear-away for quick removal and cut-away for durability.

- Proper storage and machine settings enhance each stabilizer’s effectiveness for professional-quality embroidery results.

What Are Embroidery Stabilizers and Why Do They Matter?

Have you ever wondered why some embroidered designs turn out crisp and professional-looking while others look uneven or distorted? The answer often lies in using the right embroidery stabilizer. Stabilizers provide support to your fabric during the embroidery process, preventing puckering and distortion. Proper embroidery machine settings also play a fundamental role, ensuring your machine stitches correctly without tension issues. Additionally, stabilizer storage is key—keeping it in a dry, organized place preserves its quality, so it works effectively every time. Choosing the correct stabilizer depends on your fabric type and design complexity, but understanding its purpose makes a big difference. When you combine good stabilizer storage, precise machine settings, and the right stabilizer, you set yourself up for professional-looking results every time. Moreover, selecting the appropriate embroidery technology can significantly influence the final outcome, ensuring your designs are both vibrant and durable. Being aware of fabric types and their compatibility with different stabilizers can further enhance your embroidery success. Proper knowledge of stabilizer types allows you to make informed choices tailored to each project, ultimately improving your embroidery quality. Additionally, understanding the benefits of using stabilizers can help you decide which type will best support your specific design needs.

Understanding Tear-Away Stabilizers and Their Best Uses

Tear-away stabilizers are a popular choice for many embroidery projects because they provide firm support that’s easy to remove after stitching. They work well on stable fabrics where minimal support is needed, such as woven cotton or denim. When selecting tear-away stabilizers, consider fabric compatibility to prevent puckering or distortion. Proper stabilizer storage is key to maintaining its effectiveness—keep it in a cool, dry place away from humidity. Use tear-away stabilizers for designs with dense stitching or small lettering, where excess stabilizer can be easily torn away without damaging the fabric. They are ideal for projects that don’t require long-term stabilization or where a clean finish is desired without residue. This makes tear-away stabilizers versatile and convenient for many embroidery needs. Additionally, understanding the cultural significance and stories behind embroidery designs can help you choose the appropriate stabilizer to enhance the final result. For optimal results, it’s also helpful to know about stabilizer compatibility with different fabrics and embroidery techniques. A thorough knowledge of fabric types and their compatibility with various stabilizers can help prevent issues like puckering and ensure your design looks professional and lasts over time. Being aware of the stabilizer removal process can also help in achieving a cleaner finish and avoiding fabric damage.

When to Use Cut-Away Stabilizers for Professional Results

When aiming for professional-quality embroidery, cut-away stabilizers are vital because they provide long-lasting support that keeps your design looking crisp and polished. Use them on stretchy or delicate fabrics where maintaining fabric tension is essential, as they prevent puckering or distortion. They’re especially effective with dense or intricate designs that require extra stability. Choosing the right thread can also influence your decision—high-quality, compatible threads work best with cut-away stabilizers to guarantee durability and a smooth finish. Apply cut-away stabilizers when you need a secure, permanent foundation that won’t shift or flatten over time, maintaining the integrity of your embroidery. This combination of fabric tension, thread selection, and stabilizer type gives you professional results every time.

How to Choose the Right Stabilizer for Your Project

Choosing the right stabilizer starts with understanding your fabric and design. Your choice depends on factors like fabric weight, design complexity, and desired finish. Consider these key points:

- Match stabilizer type to fabric stiffness and stretch

- Adjust thread tension to prevent puckering or loose stitches

- Select the appropriate hoop size and material for stability

- Think about the design’s detail level—more intricate designs may need more support

- Guarantee compatibility between stabilizer, fabric, and thread for smooth stitching

- Be aware of vetted stabilizer options to ensure quality and performance in your projects

- Additionally, understanding the fabric composition can help you choose the most effective stabilizer for your specific needs.

- Recognizing the fabric’s stretch and weight can further refine your stabilizer selection, ensuring optimal results.

Tips for Using Wash-Away Stabilizers for Soft, Detailed Embroidery

Using wash-away stabilizers can greatly enhance soft, detailed embroidery by providing just enough support without adding bulk. To achieve ideal results, choose a stabilizer that complements the fabric texture; delicate fabrics benefit from thinner, more transparent options. Before stitching, ensure your needle selection is appropriate—smaller, sharper needles help prevent puckering and damage, especially on fine details. Test on a scrap piece to see how the stabilizer interacts with your fabric and design, adjusting tension if needed. When finished, gently rinse the stabilizer away, avoiding excessive agitation that could distort your embroidery. This process keeps your project lightweight, soft, and highly detailed, making wash-away stabilizers ideal for intricate designs on sensitive fabrics. Understanding stabilizer types can help you select the best option for your specific project.

Frequently Asked Questions

Can Stabilizers Be Reused After Embroidery?

Stabilizers generally can’t be reused after embroidery because they lose their structure and support. When you prepare fabric, you need to select the right stabilizer for thread compatibility and project type. Reusing stabilizers might cause poor stitch quality or fabric puckering. To guarantee the best results, always use fresh stabilizers tailored to each project, and consider the specific stabilizer type—tear-away, cut-away, or wash-away—for ideal fabric preparation and thread support.

How Do Stabilizers Affect Embroidery Machine Maintenance?

Oh, the glamorous world of embroidery machine maintenance! Stabilizers, ironically, don’t directly harm your machine, but neglecting thread tension and machine lubrication can turn your project into a tangled mess. Using stabilizers improperly might cause thread jams or tension issues, forcing you to clean and service your machine more often. So, keep your tension just right and lubricate regularly—your machine will thank you, and your embroidery will stay flawless.

Are There Eco-Friendly Stabilizer Options Available?

Yes, eco-friendly stabilizer options are available. You can choose biodegradable stabilizers made from natural fibers or recycled materials, which reduce environmental impact. These options are designed to break down more easily after use, helping you stay sustainable. By selecting these environmentally conscious stabilizers, you support eco-friendly practices without compromising your embroidery quality, making your projects greener and more responsible for the planet.

What Are Common Mistakes When Choosing Stabilizers?

You often make mistakes when choosing stabilizers by not considering fabric compatibility, which leads to poor embroidery results. Additionally, neglecting stabilizer layering can cause puckering or uneven stitching. Always match the stabilizer type to your fabric’s weight and texture, and layer stabilizers properly for extra support. Avoid rushing the selection process, and test on scrap fabric to make sure your project turns out flawless.

How Do Stabilizers Influence Embroidery Speed and Efficiency?

Stabilizers directly impact your embroidery speed and efficiency by ensuring proper support and preventing errors. When you choose compatible stabilizers, your machine runs smoothly, reducing interruptions. Proper stabilizer storage keeps them in good condition, so they work effectively every time. Using the right stabilizer for each project minimizes rework, saving you time. Quickly switching stabilizers, knowing they’re compatible, helps you finish projects faster and with better quality.

Conclusion

Choosing the right embroidery stabilizer is like finding the perfect brush for a painting—you’ll want the one that brings your design to life without compromising its integrity. Whether you opt for tear-away, cut-away, or wash-away, understanding their roles helps you craft professional, polished results. With the right stabilizer in hand, you’ll turn your fabric into a canvas of intricate beauty, making every stitch a masterpiece that stands the test of time.