Laser cutting is a precise and versatile technique perfect for home crafters. It uses a focused laser beam to cut or engrave materials like wood, acrylic, or paper with smooth, intricate details. To get started, choose the right laser cutter, understand material compatibility and safety tips, and prepare your design files properly. With the right setup, you can create everything from jewelry to décor. Keep exploring to reveal more tips and project ideas.

Key Takeaways

- Choose a suitable laser cutter, like a desktop CO2 or diode model, based on project size and material compatibility.

- Understand material properties and safety precautions, including ventilation and protective gear, before cutting.

- Prepare high-quality vector design files (SVG or DXF) with clean, closed paths for precise results.

- Test small samples to optimize laser power and speed settings for different materials.

- Regularly maintain your laser equipment and follow safety protocols to ensure safe, effective crafting.

Understanding How Laser Cutting Works

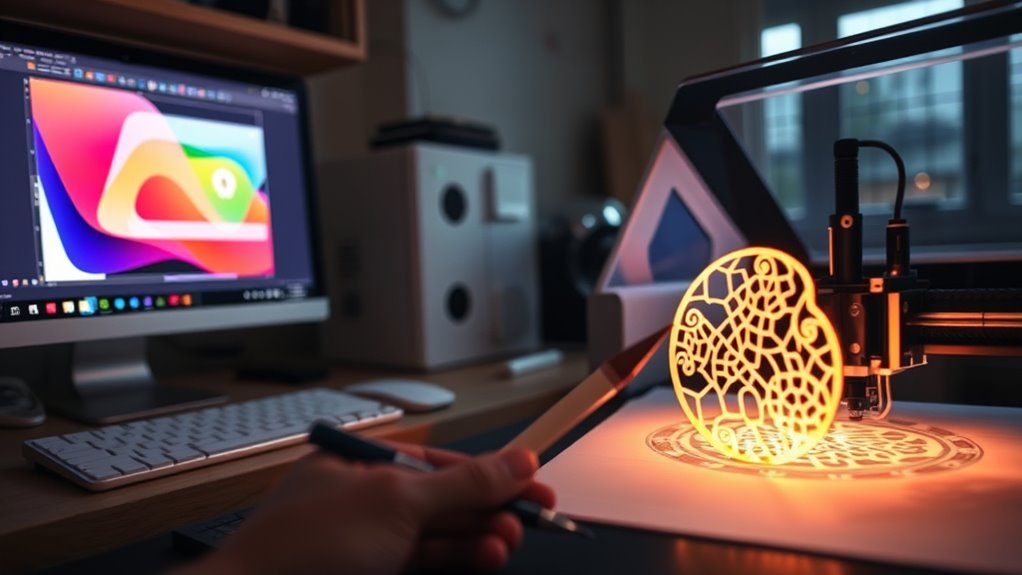

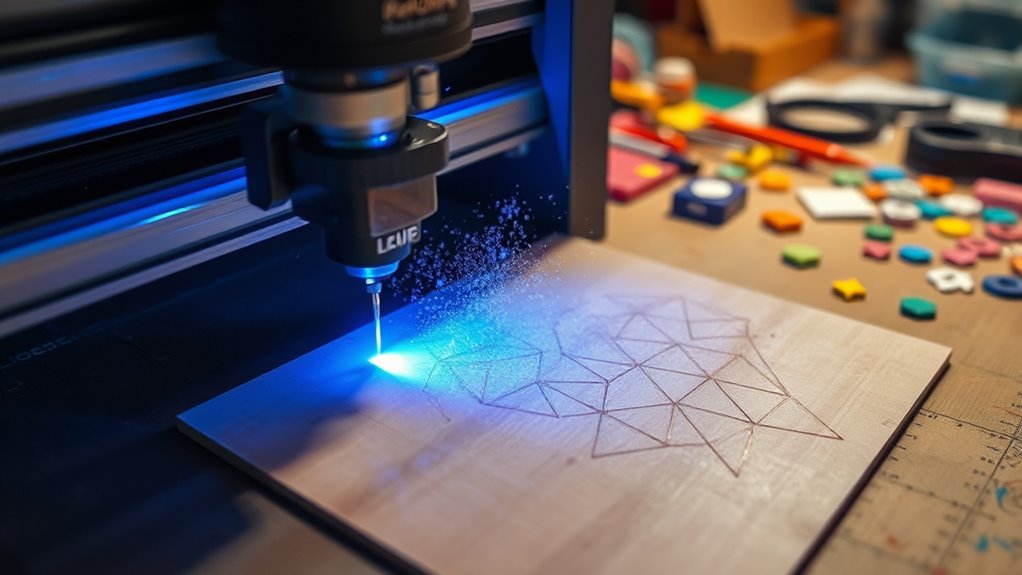

Laser cutting works by focusing a high-powered laser beam onto the material’s surface, where it heats and melts or vaporizes the material precisely. This focused laser beam creates a concentrated heat source, allowing you to cut intricate designs with high accuracy. The key to laser cutting‘s effectiveness is its exceptional cutting precision, enabling you to produce clean, smooth edges without physical contact or tool wear. As the laser beam moves along the programmed path, it melts or vaporizes the material exactly where needed. This process minimizes material waste and ensures consistent results. Whether you’re working with wood, acrylic, or metal, understanding how the laser beam interacts with your material helps you achieve professional-quality cuts every time. Additionally, knowledge of material compatibility is essential for selecting the right settings and achieving optimal results. Proper calibration and understanding of laser power settings can further enhance the quality and efficiency of your projects.

Types of Laser Cutters Suitable for Home Use

When considering laser cutters for home use, it’s important to choose a model that balances power, size, and affordability. Desktop laser cutters, like CO2 and diode types, are compact and user-friendly, perfect for small projects. CO2 laser cutters offer higher precision and are suitable for cutting thicker materials, but they may require more maintenance and troubleshooting laser cutters can be necessary over time. Diode laser engravers are more affordable, easier to maintain, and ideal for engraving and light cutting tasks. Both types fit well in a home setting, but you should assess your project needs and workspace. Regular laser cutter maintenance keeps your machine running smoothly, while troubleshooting laser cutters quickly helps avoid downtime and ensures consistent results. Proper maintenance is essential to extend the lifespan and performance of your laser cutter. Additionally, understanding the different types of laser cutters can help tailor your choice to your specific crafting projects. Incorporating knowledge of airless paint sprayers can also be beneficial for finishing projects efficiently, especially when working with large or textured surfaces. Moreover, selecting a laser cutter with air filtration technology can improve indoor air quality and safety during operation, which is especially important given the sound healing science that emphasizes the benefits of safe, health-conscious environments.

Selecting the Right Materials for Your Projects

Choosing the right materials is essential for achieving the best results with your laser projects. Different materials have unique properties that influence how they react to laser cutting, affecting both quality and safety. For example, some woods like plywood cut cleanly with minimal burn marks, while acrylic produces smooth edges but can emit fumes if not ventilated properly. Understanding material properties helps you select appropriate cutting techniques—such as power settings and speed—to prevent burns, warping, or incomplete cuts. Always verify that your material is laser-safe, avoiding plastics that release toxic fumes. Testing small samples first can save time and materials. Additionally, knowing the vibrational state of your materials can help you better predict how they will respond to laser cutting, ensuring more precise and professional-looking results in every project. Being aware of material composition is crucial, as it can influence the safety and quality of your laser-cut pieces. Considering the thermal conductivity of materials can also improve your cutting outcomes by helping you adjust your machine settings for optimal performance. For example, seasonal variations can affect how certain materials react during cutting, so adapting your approach based on environmental conditions can lead to better results. Moreover, understanding the astrological compatibility of materials might offer unique insights into their suitability for specific projects, especially when combining different types.

Preparing Your Design Files for Laser Cutting

To guarantee your design files are ready for a smooth laser cutting process, you need to prepare them carefully before sending them to the machine. Start by choosing the right design file formats, such as SVG or DXF, which preserve the precision of your vector graphics. Vector graphics are essential because they allow for clean, scalable lines without pixelation, ensuring accurate cuts. Make sure your design is clean, with closed paths and no overlapping lines, as these can cause issues during cutting. Simplify complex designs to prevent errors and reduce cutting time. Double-check that your design is properly sized for your project. Additionally, paying attention to resolution and detail can significantly impact the final outcome of your laser-cut piece. Ensuring your files are compatible with your laser cutter’s software is crucial for a seamless process, especially when considering file compatibility with different machines. It’s also important to understand material properties to select the best settings for your specific project. To ensure compatibility, confirm that your files include the correct SWIFT/BIC codes when transferring designs or information electronically. By following these steps, you’ll ensure your files are optimized for efficient, precise laser cutting.

Safety Tips and Best Practices

Ensuring safety during laser cutting is essential to prevent accidents and protect both you and your equipment. Always wear proper eye protection to shield your eyes from harmful laser beams and debris. Be aware of fire hazards; keep a fire extinguisher nearby and never leave the laser cutter unattended while in operation. Maintain a clean workspace, removing flammable materials from the area. Use the laser cutter’s safety features, like emergency stops and lids, correctly. Regularly inspect your equipment for damage or wear. Additionally, understanding the importance of amazing life together can motivate you to prioritize safety and create a secure environment for your crafting projects. Staying informed about AI in Education can also help you utilize technology responsibly and safely in your creative endeavors. Being familiar with laser safety protocols is crucial to minimize risks associated with laser cutting. It is also helpful to stay updated on skincare safety to ensure your workspace remains a healthy environment for all. Recognizing the significance of celebrity lifestyle insights can inspire a balanced approach to your hobbies, emphasizing safety alongside enjoyment.

Creative Projects to Try With Your Laser Cutter

Laser cutters open up a world of creative possibilities, allowing you to transform simple materials into intricate designs and unique crafts. You can create personalized jewelry, custom home décor, or engraved keepsakes. Try embossing techniques by etching layered patterns onto leather or paper to add texture and depth. Experiment with laser engraving tips to customize items such as photo frames, wooden plaques, or glassware. These projects let you showcase your style and make meaningful gifts. For a polished finish, combine engraving with embossing for a layered effect. Don’t be afraid to explore different materials and techniques—your laser cutter can turn basic supplies into stunning, one-of-a-kind creations that reflect your creativity.

Frequently Asked Questions

How Much Space Do I Need for a Home Laser Cutter?

You’ll need enough space to comfortably fit your laser cutter, typically around 4×2 feet, plus room for ventilation and safety precautions. Make certain there’s proper ventilation requirements to avoid fumes buildup, and leave space for safety measures like fire extinguishers and protective gear. Keep the area well-ventilated and away from flammable materials, and make sure you follow all safety precautions to keep your workspace safe and efficient.

What Is the Average Cost of a Beginner-Friendly Laser Cutter?

Thinking about the cost comparison, a beginner-friendly laser cutter is like a stepping stone—you don’t need to break the bank. On average, prices range from $200 to $2,000, depending on features like cutting size, power, and software. Consider feature considerations carefully to find one that fits your budget and crafting needs. Remember, investing wisely now saves you money and frustration later.

Can I Use My Existing Computer Software for Laser Design?

You can usually use your existing computer software for laser design, but you need to verify file compatibility first. Most laser cutters support common design software like Adobe Illustrator, CorelDRAW, or Inkscape. Confirm your software exports files in formats the laser cutter recognizes, such as SVG, DXF, or AI. Confirming file compatibility helps you avoid issues and makes your design process smoother and more efficient.

How Much Maintenance Is Required for Home Laser Cutters?

You’ll find that maintaining your home laser cutter isn’t too demanding. Following a regular maintenance schedule keeps it running smoothly and guarantees laser cutter safety. You should clean the lens and mirrors weekly, check for dust buildup, and lubricate moving parts monthly. This simple routine prevents issues and prolongs your machine’s life. Staying consistent with maintenance helps you avoid costly repairs and keeps your projects safe and efficient.

Are There Any Legal Restrictions on Home Laser Cutting Projects?

Legal limitations loom over your laser cutting projects, so you should stay savvy about safety regulations and legal considerations. Local laws may restrict certain materials, require proper ventilation, or mandate safety equipment. Ignoring these rules risks repercussions like fines or safety hazards. Before you begin, check your community’s regulations to ensure compliance and avoid avoidable issues. Staying informed keeps your creative craft consistent, safe, and compliant with all legal considerations.

Conclusion

Just as Da Vinci unleashed boundless creativity, your laser cutter opens a world of possibilities. With the right knowledge and safety habits, you’ll craft masterpieces that rival the greats. Embrace your inner artist, experiment boldly, and remember that every cut is a step toward mastery. Your journey is a modern renaissance—where precision meets imagination, turning raw materials into timeless art. The future of your crafting adventure starts now; let your imagination lead the way.