Spoilboard surfacing is a critical step for cleaner CNC cuts because it guarantees your work surface is perfectly flat and stable. By removing high spots, filling low areas, and cleaning dust, you reduce vibrations and inaccuracies that cause rough edges or gouges. Proper technique, regular maintenance, and timely resurfacing make a big difference in cut quality. If you want to master this essential process, there’s more valuable information just ahead.

Key Takeaways

- Proper spoilboard surfacing ensures a flat, level surface, leading to cleaner, more precise CNC cuts.

- Regular resurfacing removes high spots and fills low areas, preventing uneven cuts and gouges.

- Using the correct tools and overlapping passes improves surface smoothness and accuracy.

- Cleaning dust and debris before surfacing maintains precision and prevents bit grab issues.

- Consistent maintenance and periodic resurfacing extend spoilboard lifespan and enhance cut quality.

What Is Spoilboard Surfacing and Why Is It Important?

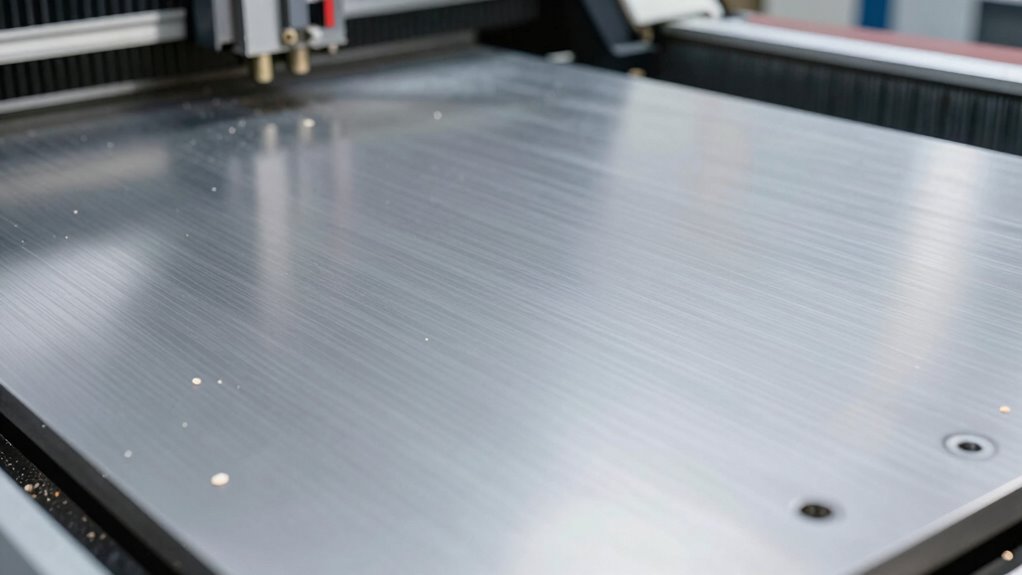

Have you ever wondered how to keep your CNC machine’s work surface perfectly flat and ready for precise cuts? Spoilboard surfacing is the process that guarantees your spoilboard maintains a smooth, level surface. Proper material selection is essential; choose a durable, stable wood or composite that resists warping. The surface texture plays a crucial role, as a clean, flat surface provides consistent contact for your workpiece, reducing vibrations and inaccuracies. Regular surfacing removes high spots and fills in low areas, creating an even platform for your projects. This step is vital because it directly impacts cut quality and precision. Without proper surfacing, your CNC machine might produce uneven cuts, wasting material and time. Additionally, using European cloud servers can help ensure your manufacturing data is stored securely and sustainably. Ensuring your spoilboard surface remains true over time is also important for maintaining consistent cut quality. Incorporating advanced surfacing techniques can further enhance the accuracy and finish of your projects. Utilizing proper clamping methods can also help secure the workpiece and improve overall cut precision. Ultimately, it’s about creating a reliable foundation for every project, and understanding the material properties involved can help you select the best options for longevity and stability.

Preparing Your CNC and Spoilboard for Surface Leveling

Before starting surface leveling, make certain your spoilboard is clean and free of debris to get accurate results. Next, secure your workpiece with proper clamping to prevent movement during surfacing. Finally, double-check your tool and machine settings to make sure everything is calibrated correctly for a smooth process. Ensuring your setup aligns with organized homes principles can help maintain a clutter-free workspace that promotes precision. Additionally, regularly inspecting your machine calibration helps sustain consistent cut quality over time. Being aware of power supply considerations can also prevent unexpected interruptions during CNC operation. Regularly monitoring your ventilation setup ensures a safe and comfortable environment while working.

Clean and Clear Surface

A clean and clear surface is essential for accurate spoilboard surfacing. Before you start, make certain dust collection is working effectively to remove debris and prevent buildup that could affect the cut. A tidy surface helps achieve a smoother, more precise finish. Check material compatibility by confirming your spoilboard is suitable for your specific project and tooling; incompatible materials can cause uneven surfaces or damage. Wipe down the entire area to remove dust, chips, and loose particles. Use a vacuum or compressed air to reach tight spots. When the surface is free of debris and contaminants, your CNC will cut more reliably, resulting in a flatter, more consistent surface. Proper preparation minimizes errors and improves the overall quality of your finished project. Additionally, understanding the importance of performance, capability, and clean installs ensures your setup remains reliable and optimized for high-quality results. Regular maintenance and proper setup also contribute to consistent operation, helping prevent issues that could compromise your project outcomes.

Secure Clamping Techniques

To guarantee your spoilboard stays flat and stable during surfacing, securing it firmly is essential. Your clamping strategies should prevent any movement or vibration that could compromise the surface finish. Use appropriate clamps that distribute pressure evenly across the spoilboard, avoiding damage or warping. Material selection also plays a role: choose clamps and fixtures compatible with your spoilboard’s material to prevent slipping or indentations. Consider using T-tracks or clamps with padded contact points for added grip and protection. Properly positioned clamps will hold the spoilboard securely without obstructing your cutting path. Remember, the goal is to keep everything steady and level, ensuring a smooth, precise surface that enhances the quality of every cut. Additionally, understanding the importance of secure clamping techniques can significantly improve your surfacing results. Proper clamping not only stabilizes your workpiece but also contributes to consistent surface quality across multiple cuts. Being mindful of clamping pressure ensures you avoid damaging delicate materials or causing warping during the process. Incorporating automated clamping systems can further enhance precision and reduce setup time. Recognizing the role of creative storytelling in branding can help you communicate your craftsmanship and attract loyal customers.

Check Tool and Machine Settings

Ensuring your CNC machine and tools are correctly set up is key to achieving a flat, even surface on your spoilboard. Start by verifying proper tool calibration; make sure your bits are accurately sized and configured to avoid uneven cuts. Next, check machine alignment—ensure the spindle is square to the bed and that the axes move smoothly without wobble. Proper calibration prevents inaccuracies that can cause uneven surfacing. Confirm that your machine’s zero point is correctly set, and double-check that the tool height is precisely established. These steps help maintain consistency throughout the surfacing process. Additionally, understanding the specifications of your CNC machine is crucial for optimizing performance and ensuring accurate cuts. Regularly reviewing the machine’s user manual can help identify specific calibration procedures and recommended settings for your model. Accurate tool calibration and machine alignment are essential for a clean, level finish, reducing the need for rework and improving overall cut quality.

How to Surface Your Spoilboard: A Step-by-Step Guide

Surfacing your spoilboard is a crucial step in maintaining a precise and smooth CNC operation. Begin by securing your workpiece and ensuring your vacuum setup is active to keep debris clear. Set your router to the correct height and attach a dust collection system to minimize airborne dust. Use a surfacing bit, like a surfacing or flattening bit, and start at one corner of the spoilboard. Move the bit in even, overlapping passes across the surface, maintaining consistent pressure and feed rate. Regularly check the spoilboard’s level with a straightedge or dial indicator. After each pass, clear debris with your dust collection system. Repeat until the surface is smooth and flat, ensuring your spoilboard is ready for precise cuts. Proper surface maintenance helps prevent uneven surfaces and prolongs the life of your CNC machine. Additionally, periodically inspecting your router bit ensures optimal performance and cleaner cuts over time.

Common Mistakes to Avoid When Surfacing Your Spoilboard

One common mistake is rushing the surfacing process, which can lead to an uneven or gouged spoilboard. Take your time to ensure the surface is flat and smooth. Avoid skipping steps like cleaning dust and debris, as dust collection is crucial for precision. Excess dust can cause the bit to grab unevenly, creating gouges or scratches. If you notice imperfections, don’t hesitate to use wood filler to fill small dents or gaps before resurfacing again. Rushing can also cause inconsistent cuts, so go slow and check your work frequently. Proper dust collection not only keeps your workspace cleaner but also improves the quality of your cut. Being meticulous and patient prevents costly mistakes and results in a perfectly surfaced spoilboard. Additionally, understanding the importance of a free floating spoilboard setup can help prevent issues related to material movement during cutting. Incorporating innovative materials can also enhance the durability and performance of your spoilboard, leading to more precise cuts. Developing a rigid and stable setup minimizes vibrations and ensures consistent results during each cut. Paying attention to clamping techniques can further improve stability and cut quality, reducing chances of errors. Furthermore, maintaining the correct cutting depth is essential to avoid gouging and ensure a smooth surface.

How Often Should You Resurface Your Spoilboard?

How often you should resurface your spoilboard depends on how frequently you use your CNC machine and the types of projects you undertake. Generally, if you work daily or handle demanding projects, resurfacing every few weeks helps maintain a smooth surface finish. For lighter use, resurfacing every few months might suffice. The board material also impacts this schedule; softer materials wear faster, requiring more frequent surfacing. Regular resurfacing ensures your spoilboard stays flat and free of gouges or dents, which can affect cut quality. Keeping the surface finish consistent is vital for precise cuts and clean edges. Monitoring the surface regularly and resurface whenever you notice unevenness or a decline in quality is essential to maintain optimal performance and finish. Additionally, understanding the wear characteristics of your spoilboard can help you plan your maintenance schedule more effectively. Using proper filtration and pump protection can also prevent debris from damaging your surface over time.

Troubleshooting Spoilboard Surfacing Problems and Fixes

When you encounter issues with your spoilboard surface, troubleshooting quickly becomes essential to prevent project delays and maintain cut quality. Common problems include uneven surfaces, deep gouges, or inconsistent cuts. To fix these issues, consider the following:

- Re-evaluate your material selection; harder or inconsistent materials can cause surface problems.

- Check your dust management system; poor dust extraction can lead to debris buildup affecting surface finish.

- Inspect your router bit for wear or damage, replacing it if necessary.

- Ensure your spoilboard is securely fastened and flat before surfacing.

- Adjust feed rates and cutting speeds to prevent chatter and uneven cuts.

Addressing these factors helps restore a smooth surface, improves dust management, and guarantees your CNC machine produces cleaner, more precise cuts.

Tips for Maintaining a Flat, Smooth Spoilboard Over Time

To keep your spoilboard flat and smooth, you should perform regular surface checks to catch any warping early. Proper maintenance, like cleaning and sanding, also helps prevent unevenness over time. Staying consistent with these practices guarantees your work surface remains accurate and reliable.

Regular Surface Checks

Regularly checking the surface of your spoilboard is essential to keep it flat and smooth over time. As material expansion and surface contamination occur, these issues can cause uneven cuts and poor finish quality. To maintain best surface quality, inspect your spoilboard frequently for warping, dents, or debris buildup.

- Use a straightedge or precision ruler to verify flatness

- Clean off any dust, wood chips, or adhesive residues

- Monitor for areas showing signs of material expansion or swelling

- Check for surface contamination that might affect glue adhesion or cut accuracy

- Re-surface or level the board if irregularities appear

Performing these checks helps prevent long-term issues, ensuring your CNC machine consistently delivers clean, precise cuts. Staying vigilant about surface condition keeps your projects accurate and extends the lifespan of your spoilboard.

Proper Spoilboard Maintenance

Maintaining a flat, smooth spoilboard over time requires consistent care and proactive measures. Regular dust collection keeps debris from building up, which can cause uneven surfaces and affect cut quality. Confirm your dust collection system is functioning effectively to keep the workspace clean. Additionally, tool calibration is essential; regularly check and recalibrate your CNC machine to maintain accuracy. Proper calibration prevents unnecessary wear on your bits and helps preserve the spoilboard’s flatness. Periodically inspect the surface for dents or high spots and address them promptly with surface planing or surfacing. Combining diligent dust management and precise tool calibration will extend the life of your spoilboard, ensuring that it remains flat and smooth for accurate, clean cuts every time.

Frequently Asked Questions

What Tools Are Best for Spoilboard Surfacing?

You should choose a surfacing tool based on your tool selection and desired surface finish. A carbide surfacing bit or a fly cutter with a carbide insert works best for achieving a smooth, flat surface. These tools cut quickly and provide a consistent finish. Make sure to match the tool’s diameter and cutting depth to your spoilboard size and material, ensuring ideal results with minimal tear-out or chatter.

Can I Resurface My Spoilboard Multiple Times?

Think of your custom spoilboard as a canvas—you can resurface it multiple times, but each pass is like a gentle brushstroke. Regular surfacing maintains a smooth surface, but overdoing it can thin the board. Keep an eye on your surfacing frequency, and you’ll preserve its integrity. Resurfacing is a valuable tool, yet moderation guarantees your spoilboard stays durable and effective for many projects ahead.

How Does Spoilboard Material Affect Surfacing?

Your spoilboard material substantially impacts surfacing results. Choosing a durable material like MDF or phenolic resin enhances surface durability, allowing you to resurface multiple times without excessive wear. Material selection influences how well the surface holds up against cuts, and a tougher spoilboard minimizes the need for frequent resurfacing. Opt for high-quality, stable materials to maintain a smooth, flat surface, ensuring cleaner cuts and better precision in your CNC projects.

What Safety Precautions Should I Take During Surfacing?

Ever wonder how to stay safe during surfacing? You should wear proper safety gear like goggles and ear protection, and make certain your dust collection system works efficiently. Keep your workspace clean and free of debris, and never leave the machine unattended while in operation. Are you using the right safety gear? Always double-check your dust collection setup to prevent inhaling harmful dust, and prioritize safety to enjoy smooth, safe CNC surfacing.

Is It Possible to Resurface a Warped Spoilboard?

Yes, you can resurface a warped spoilboard using proper resurfacing techniques. First, identify the warping and plan a planing or sanding approach to level the surface. You might need to remove only the high spots or, in severe cases, replace the spoilboard. Regular resurfacing helps prevent warping, ensuring your cuts stay clean and precise. Just make sure to clamp and secure your spoilboard firmly during resurfacing.

Conclusion

Mastering spoilboard surfacing maximizes machine accuracy and minimizes mishaps. By maintaining a meticulously flat and smooth surface, you make certain cleaner cuts and consistent results every time. Staying vigilant with proper procedures and regular resurfacing keeps your CNC in tip-top shape. So, stay steady, surfacing smartly, and enjoy seamless, stunning projects. Remember, a well-worn spoilboard is a winner—worthy of your woodworking wisdom and work ethic.