To achieve support success, focus on proper placement, adjusting support density, and choosing the right materials. Place supports beneath overhangs and at critical points, but avoid cluttering detailed areas. Use minimal supports for easier removal and guarantee they’re compatible with your resin. Post-processing with gentle tools and techniques also prevents damage. Following these steps greatly reduces support failures—if you want to learn more, there’s plenty of expert advice that can help improve your prints.

Key Takeaways

- Properly place supports beneath overhangs and critical features to prevent failure and facilitate easy removal.

- Optimize support density—use minimal supports to maintain stability while easing post-processing.

- Select compatible support materials with smooth surfaces and low adhesion for easier detachment.

- Adjust support placement based on resin properties and print geometry to ensure reliable adhesion.

- Use gentle removal techniques and tools to prevent surface damage and maintain print quality.

Why Do Support Failures Happen in Resin Printing?

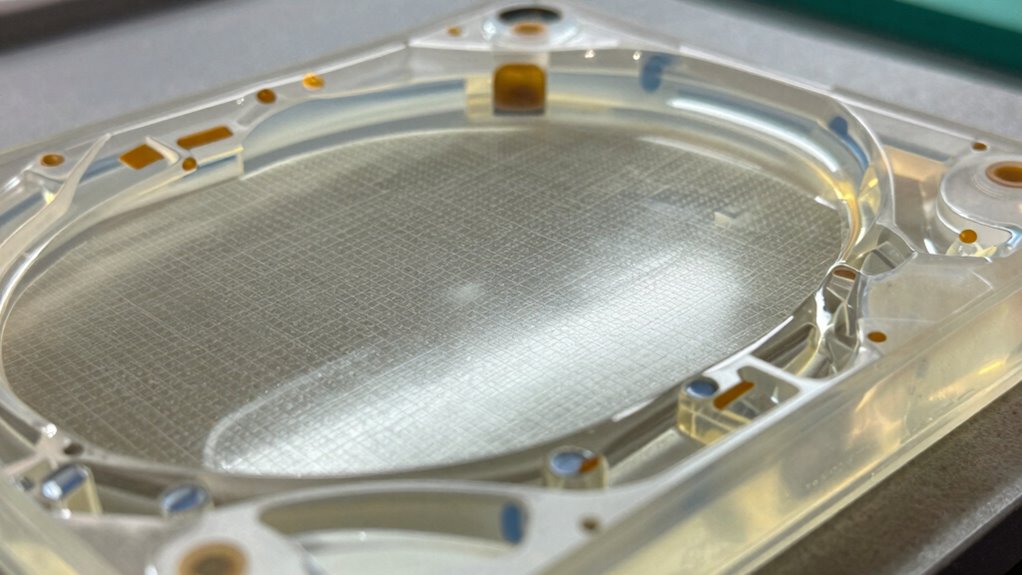

Support failures in resin printing often occur because the supports aren’t properly designed or positioned. Poor support adhesion can cause supports to detach during the print, leading to layer shifts or print failure. One common reason is that the supports aren’t optimized for the resin’s compatibility; different resins have varying curing properties and surface tension, which affects how well supports stay attached. If supports aren’t sufficiently anchored or are placed incorrectly, they won’t hold the model securely. Additionally, using supports incompatible with your resin can weaken their bond, increasing the risk of failure. Ensuring proper support design and understanding your resin’s compatibility are key to preventing these issues. When supports are correctly placed and suited to your resin, you’ll achieve more reliable, high-quality prints. Moreover, support adhesion can be improved by adjusting print settings or using adhesion aids to enhance stability, especially when considering resin properties and how they influence support effectiveness. Properly selecting and customizing supports based on the surface tension of your resin can greatly improve success rates.

How to Choose Support Placement for Reliable Prints

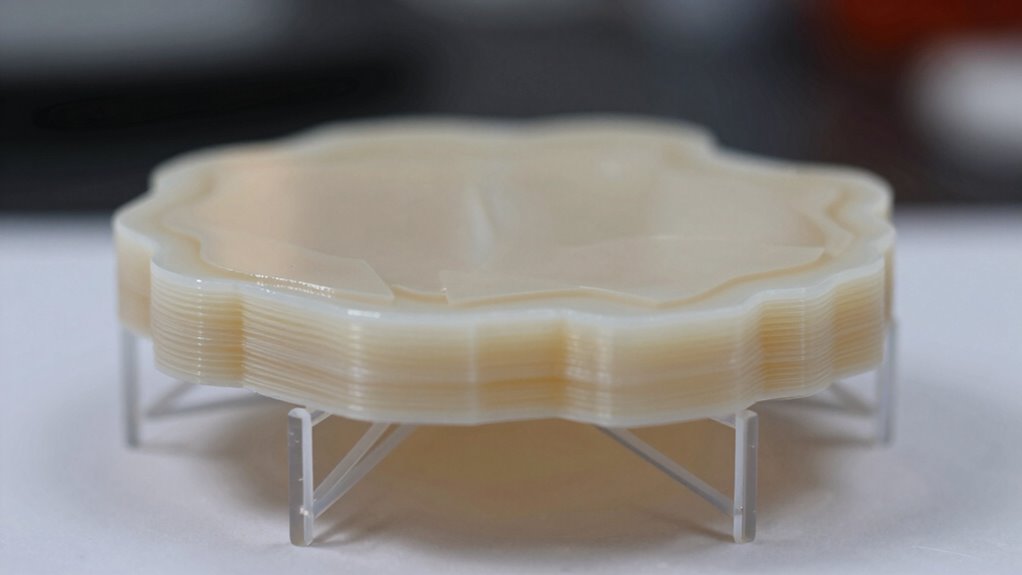

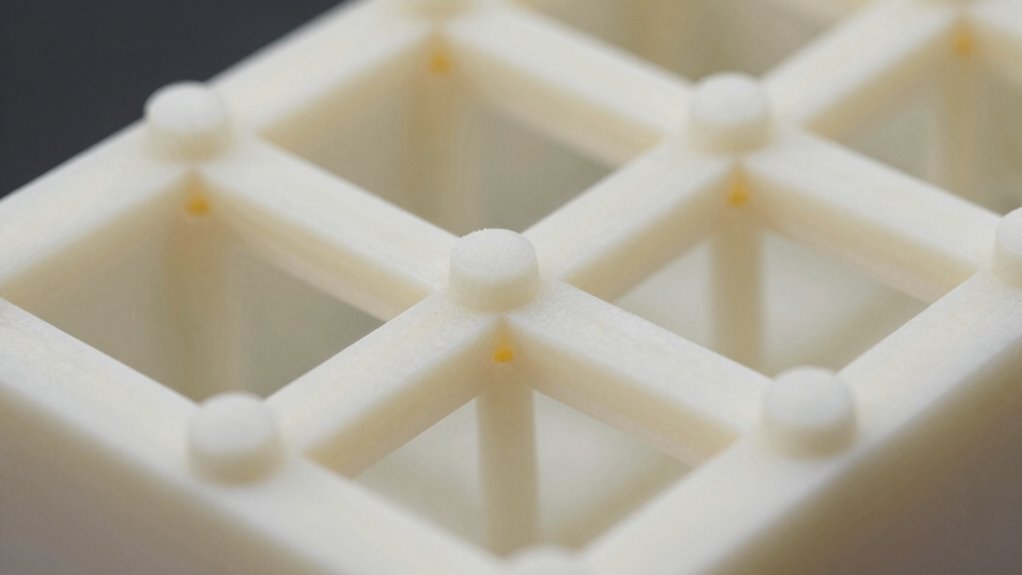

Choosing the right placement for supports is essential to guarantee your resin prints are both reliable and high quality. Start by analyzing the support grid to identify areas prone to failure, especially overhangs that need extra support. Support overhangs should be positioned carefully to prevent sagging or detachment. Place supports directly beneath complex features or steep angles to ensure stability during curing. Avoid excessive support density, which can damage surface quality, but don’t leave critical overhangs unsupported. Focus support placement on areas where the model’s geometry requires reinforcement, ensuring they are accessible for removal without risking damage. Proper support positioning minimizes failures, improves surface finish, and saves you time in post-processing. Additionally, understanding the support structure design can help optimize support placement for even better results.

Designing Supports That Are Easy to Remove and Stay Strong

To make your supports easier to remove, you need to optimize their placement so they don’t damage your print. Choosing the right release materials can also make a big difference in how smoothly they come off. Finding the right balance between support strength and easy removal guarantees your prints stay strong without extra hassle. Additionally, understanding support removal techniques can help you achieve cleaner results and reduce post-processing time. Being mindful of support placement can further prevent common issues like surface blemishes or accidental breakage during removal. Incorporating support material compatibility knowledge can further enhance the effectiveness of your support strategies. Exploring support design principles can also contribute to more efficient and reliable print outcomes. Moreover, selecting appropriate support structures tailored to your specific print can significantly improve overall results and ease of removal.

Optimizing Support Placement

Proper support placement is essential for achieving strong, clean resin prints that are easy to remove afterward. To do this, position your supports where they provide maximum stability without damaging detailed areas. Focus support material on larger, less visible surfaces to minimize contact points. Use minimal supports on delicate features, ensuring they’re placed at natural contact points to reduce breakage during support removal. Avoid crowding supports, which can make removal difficult and increase the risk of damaging the print. Instead, space supports evenly, balancing support strength with ease of removal. Remember, the goal is to create a support structure that holds the model securely during printing while remaining straightforward to detach without compromising the print’s quality. Proper placement makes all the difference. Understanding resin behavior can help predict how supports will impact the final surface quality and ease of removal. Additionally, considering resin flow during printing can help optimize support positioning for better adhesion and easier cleanup. Being aware of print orientation also plays a crucial role in support effectiveness and removal ease. Recognizing how support design influences print stability and post-processing can further improve your results.

Choosing Easy-Release Materials

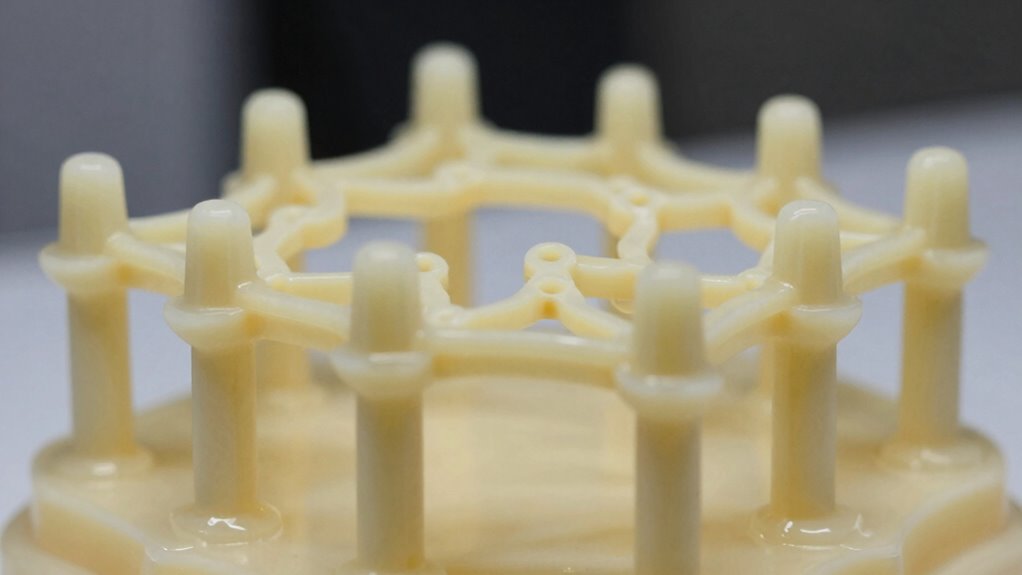

Selecting the right support material can greatly simplify the removal process without compromising the print’s integrity. Look for support materials that are designed to be easy to detach, reducing the risk of damaging your print. Using support materials with smooth surfaces or lower adhesion can make removal smoother. Additionally, applying release agents to the build plate or support points can further ease detachment. These agents act as a barrier, preventing the support material from bonding too strongly to the resin surface. Choosing support materials labeled as easy-release or compatible with release agents for best results ensures a smoother separation process. Proper support selection can also prevent damaging movements during removal, ensuring a more reliable and high-quality finish. Incorporating support removal techniques that are gentle and controlled can further enhance your success rate and minimize post-processing work.

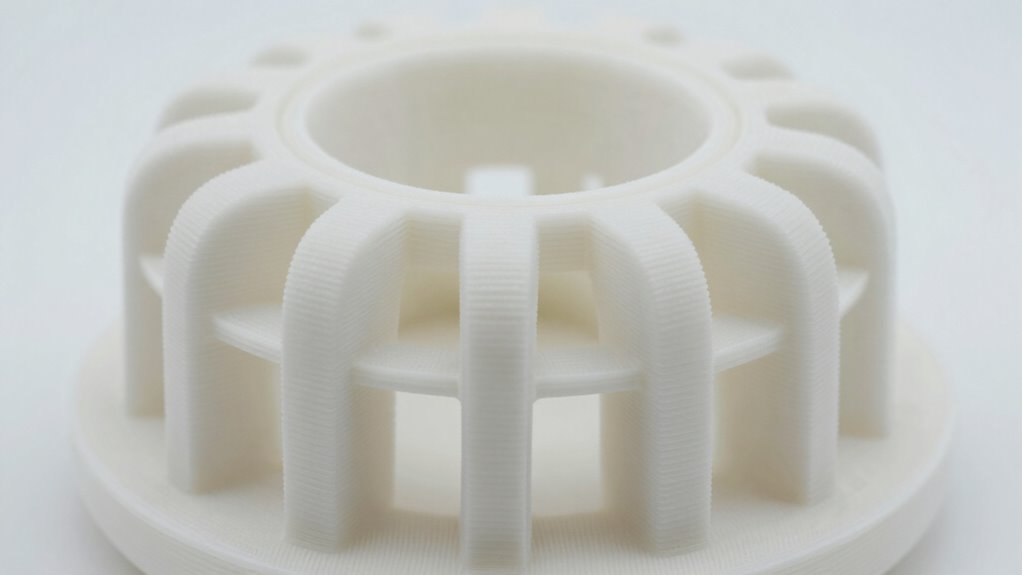

Balancing Support Strength

Have you ever struggled to remove supports without damaging your print? Balancing support strength is key. You want support material to hold your print securely during curing but still come off easily afterward. Adjust support density based on your print’s orientation; a vertical print might need stronger supports at the base. Use finer support tips where possible to make removal easier. Here’s a quick guide:

| Support Material | Print Orientation |

|---|---|

| Softer resin | Vertical surfaces |

| Harder resin | Horizontal surfaces |

| Fine tips | Angled surfaces |

| Dense bases | Overhangs |

Being mindful of material properties ensures optimal support performance and easier removal. Additionally, understanding the mechanical strength of your resin can help you choose the appropriate support settings for durability without sacrificing removability. Recognizing how support design principles influence ease of support removal can further improve your print results. Paying attention to support removal techniques can also help prevent damage during disassembly. Moreover, considering resin curing behaviors can optimize the overall support removal process and reduce risks of print failure.

Setting Up Support Settings in Your Slicer for Best Results

To get the best results, you need to carefully adjust your support settings in your slicer. Focus on ideal support placement to guarantee stability without damaging your print, and fine-tune support density to balance strength and ease of removal. Small adjustments can make a big difference in the quality and success of your resin prints. Understanding the importance of support removal techniques can also help prevent damage to your print’s surface and improve overall finish. Additionally, experimenting with support interface layers can further enhance ease of removal and surface quality. Recognizing that support design and configuration play a vital role in print success can help optimize your overall printing process, especially when considering support customization options available in many slicers. Incorporating adaptive support structures can also improve print stability and reduce material use, leading to more efficient printing outcomes.

Optimal Support Placement

Proper support placement is crucial for achieving high-quality resin prints, as it directly impacts surface finish and structural integrity. You should position supports where they won’t interfere with detailed areas, making support removal easier and minimizing surface imperfections. Place supports beneath overhangs and bridging sections, but avoid unnecessary supports that can increase cleanup time. Use support material efficiently by choosing appropriate contact points; too many can complicate removal, while too few may compromise stability. Ensure supports are spaced to provide adequate adhesion without damaging delicate features. Proper placement reduces the risk of print failures and makes support removal smoother. Focus on strategic support positioning to balance stability and ease of cleanup, resulting in a cleaner, more precise final print.

Fine-Tuning Support Density

Adjusting support density in your slicer settings is essential for finding the right balance between stability and ease of removal. If support density is too high, supports become difficult to remove and may damage your print, especially affecting print adhesion. Conversely, too low support density risks insufficient support, leading to print failures or sagging. Fine-tuning support density allows you to optimize print adhesion without overloading your print with unnecessary supports. Start by lowering support density slightly to improve removal, then test to see if stability remains. Increasing support density provides more stability for complex geometries. Remember, the goal is to find a support density that offers reliable print adhesion while making support removal simple, ensuring your resin prints come out clean and accurate every time. Adjusting support density also impacts the overall print quality, making it a crucial setting to optimize. Additionally, understanding the resin curing process can help you better anticipate how support structures will behave during printing and post-processing.

Common Mistakes That Cause Support Problems: and How to Avoid Them

One common mistake that causes support problems is neglecting proper support placement and density. If you don’t position supports where needed or set the right support material, your print can fail or require extensive post-processing. Using support material incompatible with your resin can lead to poor adhesion or damage during removal. Always ensure your support points are strategically placed under overhangs and critical areas, with enough density to hold the model securely. Check resin compatibility before selecting support material to avoid chemical reactions or weak bonds. This attention prevents supports from breaking or failing during printing. Proper support placement and compatible support material are essential for a smooth printing process and reliable results.

Tips for Post-Processing Supports Without Breaking Your Print

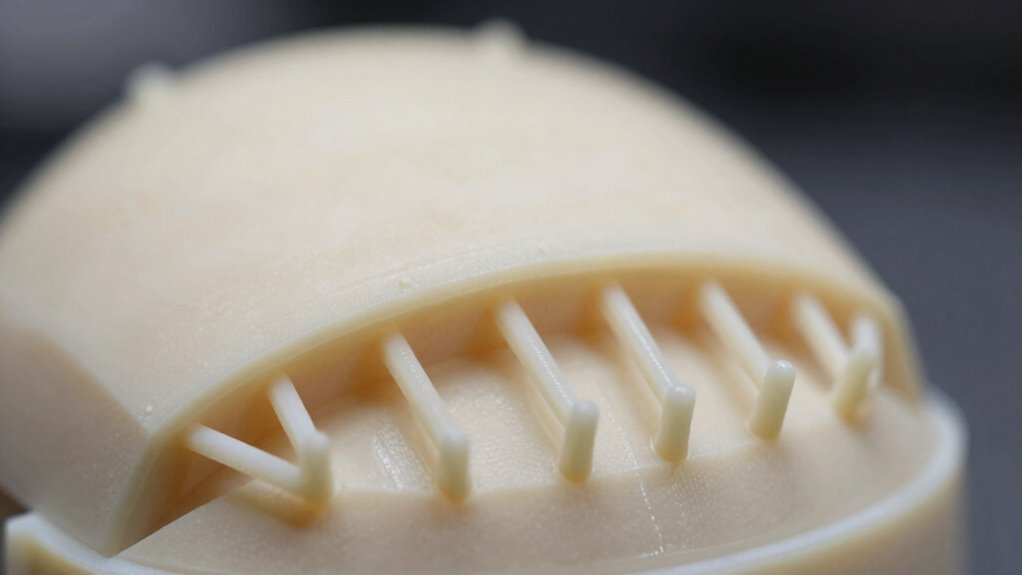

Removing supports from your resin print can be tricky, but with the right techniques, you can do it without causing damage. The key is to handle support removal carefully, especially when dealing with support material attached to delicate areas.

Here are three tips to help:

- Use fine tools like flush cutters or tweezers to gently lift and clip support material, minimizing stress on the print.

- Work slowly and steadily, applying gentle pressure to avoid cracks or breaks.

- Soften the support material with a brief dip in isopropyl alcohol if needed, making support removal smoother.

Troubleshooting Support Failures When Things Go Wrong

Support failures can be frustrating, especially when they threaten to ruin your print. If your support material doesn’t hold or detaches during printing, check the initial adhesion and support settings. It might be that supports aren’t thick enough or aren’t properly placed. During the curing process, supports can also become weak if exposed unevenly or if the resin isn’t fully cured. To troubleshoot, ensure support structures are adequately sized and properly attached, especially at critical points. Double-check your curing process, making sure the UV light penetrates evenly, and avoid overexposure, which can cause support material to become brittle. Adjusting support density and curing time can greatly improve support reliability, preventing failures and ensuring a smoother, more successful print.

Frequently Asked Questions

Can Different Resin Types Affect Support Adhesion and Failure Rates?

Different resin types can definitely affect support adhesion and failure rates. You need to take resin compatibility into account to ensure supports stick well without causing damage during support removal. Some resins may require adjustments in support settings or post-processing techniques. By choosing the right resin and optimizing your support structure, you improve adhesion and minimize failures, making support removal easier and more effective.

How Does Ambient Temperature Influence Support Success During Printing?

Temperature tricks can truly temper your prints’ triumphs. You’ll find that maintaining temperature stability is essential; fluctuations can cause support failure. Keep an eye on ambient humidity too, as high humidity can hinder adhesion and cause warping. By controlling your environment—keeping temps steady and humidity low—you boost support success, ensuring your resin prints stay solid and support confidently, reducing failures and frustration.

Are There Specific Support Designs Best for Complex Geometries?

For complex geometries, you should focus on strategic support placement and adjusting support density. Place supports at critical overhangs and areas prone to sagging, ensuring they’re close enough for stability but not so dense that removal becomes difficult. Using a moderate support density provides enough stability without excessive cleanup. By carefully selecting support placement and balancing support density, you’ll achieve more reliable, high-quality resin prints on intricate models.

What Impact Does Print Orientation Have on Support Stability?

Think of print orientation as the backbone of your success; it directly impacts support stability. When you choose the right orientation, you reduce overhangs and minimize the need for excessive supports, making your print more stable and less prone to failure. Properly aligning your model guarantees that supports are well-placed, providing a sturdy foundation that keeps your resin print intact and accurate throughout the process.

How Do I Optimize Supports for Large, Detailed Models?

To optimize supports for large, detailed models, increase support density in areas with fine details to prevent sagging. Use enough contact points to guarantee stability without damaging the surface. Position supports strategically, avoiding overly crowded contact points that can cause marks. Adjust support thickness for strength, but keep it minimal to facilitate easy removal. Regularly review and customize supports in your slicing software for the best balance of support and finish quality.

Conclusion

By following these simple yet powerful strategies, you can turn your resin printing failures into flawless masterpieces. Think of your supports as the backbone of your print—when they’re reliable, your results are unstoppable. With careful placement, smart design, and proper post-processing, you’ll conquer support issues like a seasoned pro. Remember, mastering support techniques isn’t just a skill; it’s the key to accessing print perfection in a world where even the tiniest flaw can feel like a catastrophe.