To guarantee your workpiece doesn’t slip mid-cut, choose the right workholding devices that match your material and project needs. Use strong, adjustable clamps or vises that distribute pressure evenly and resist cutting forces. Properly set up your fixtures, tighten clamps just enough, and regularly inspect for wear or misalignment. By following these best practices, you’ll improve stability. Keep going to discover more tips that will keep your projects secure and accurate.

Key Takeaways

- Choose workholding devices with strong, adjustable clamping mechanisms that resist high cutting forces during machining.

- Ensure workpiece and clamp material compatibility to prevent slipping or damage under pressure.

- Properly distribute clamping force evenly to avoid workpiece deformation and enhance stability.

- Use appropriate fixtures and supports tailored to workpiece shape and size for secure holding.

- Regularly inspect and maintain fixtures to identify wear, misalignment, or damage that could cause slipping.

Common Causes of Workpiece Slips in CNC Machining

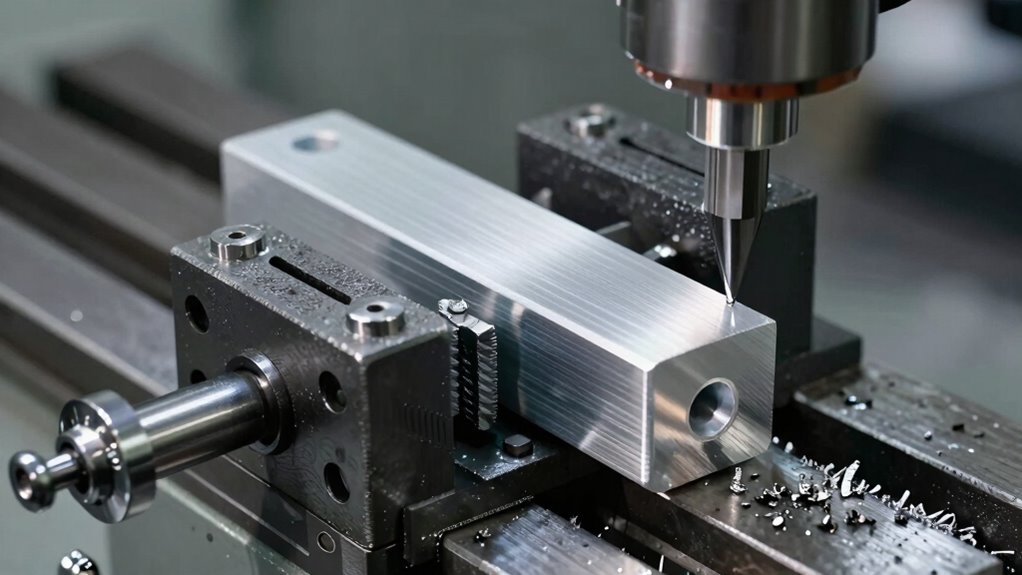

Workpiece slips during CNC machining often happen because the workpiece isn’t securely held in place. One common cause is insufficient clamping force, which fails to counteract the cutting forces and allows movement. If the clamping pressure is too weak, the workpiece can shift or slip, ruining precision. Another factor is material compatibility; some materials, like plastics or delicate composites, may require specialized clamps or softer gripping methods to prevent slipping or damage. Using incompatible clamps or improper setup can lead to uneven force distribution and reduce holding power. Ensuring your clamping force is appropriate for the material and workpiece size helps prevent slips. Properly matching clamps to your workpiece material also minimizes the risk of slippage, improving the accuracy and safety of your CNC machining process. Additionally, understanding the importance of workholding technology can help you select more effective solutions for securing your workpieces. Employing secure fastening methods tailored to your specific application further enhances stability and reduces the likelihood of movement during cutting. Regularly inspecting and maintaining your clamping equipment also ensures consistent performance and reduces the risk of unexpected slips. Incorporating the right workholding strategies can significantly improve your machining outcomes and prevent costly errors. Using advanced clamping techniques can further optimize stability and reduce setup time for complex projects.

How to Choose the Right Workholding Devices for Your CNC Projects

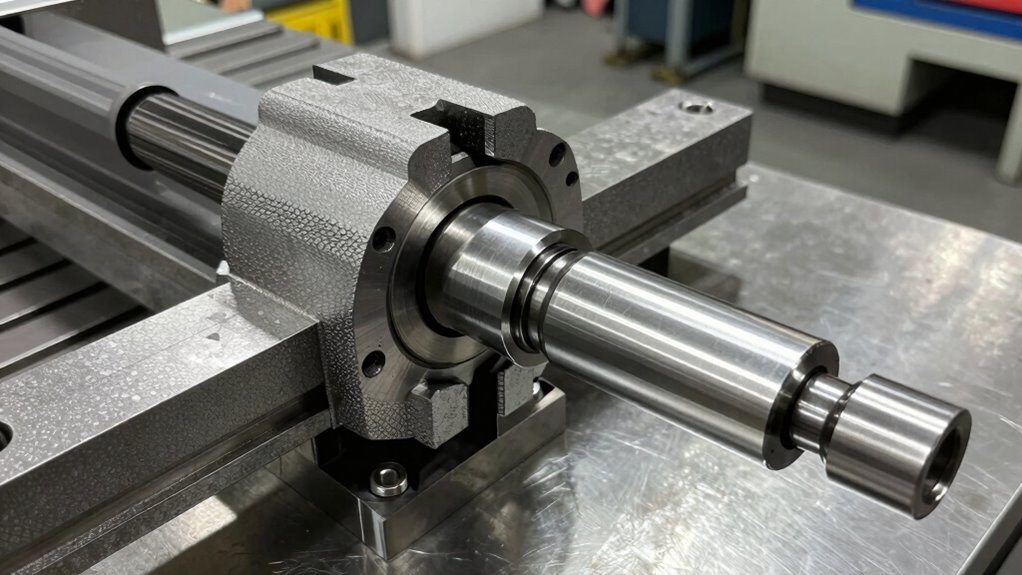

Choosing the right workholding device begins with understanding your specific project requirements. Start by evaluating your material’s compatibility with different clamping techniques, as some materials may require gentler or more secure methods. Consider the shape and size of your workpiece to select a device that provides adequate support without causing damage. Think about the type of cut you’ll perform—roughing or finishing—as this influences the holding strength needed. Confirm the workholding device can handle the forces involved without slipping or deforming the material. Compatibility with your CNC machine is also critical; verify that the device fits your setup and allows easy access for tooling. Making informed choices based on these factors helps prevent slips and ensures precise, safe cuts. Incorporating innovative cloud solutions can also streamline your workflow and improve overall project management.

Features of Reliable Workholding Devices to Prevent Slips

Reliable workholding devices incorporate key features that actively prevent slips during machining. First, strong clamping mechanisms ensure the workpiece stays securely in place, resisting forces from cuts. Second, proper material compatibility guarantees the device doesn’t damage or deform your workpiece, especially with delicate materials. Third, adjustable components let you customize grip strength and positioning for different projects, enhancing stability. Here’s a quick overview:

| Feature | Benefit | Example Use Case |

|---|---|---|

| Clamping Mechanisms | Secure hold, prevent movement | Metalwork with high cutting forces |

| Material Compatibility | Prevents damage, ensures stability | Soft woods or plastics |

| Adjustability | Custom fit, accommodates various shapes | Complex or irregular pieces |

These features work together to keep your workpiece firmly in place, reducing slips and improving precision.

Best Practices for Securing Workpieces During CNC Machining

To guarantee safe and accurate CNC machining, securing your workpiece properly is essential. Start by selecting the right clamping techniques that suit your material and project. For example, use vise jaws or clamps that distribute pressure evenly to prevent deformation or damage. Ensure your clamping devices are compatible with the material’s properties—softer materials may require softer jaw inserts, while harder materials need robust fixtures. Always check that clamps are tight but not overly so, as excessive force can cause warping or inaccuracies. Maintain consistent contact points to avoid slippage during cutting. Proper setup minimizes vibrations and movement, resulting in cleaner cuts and safer operation. Additionally, employing proper workholding methods can significantly enhance stability and precision during machining. Using quality fixtures and adjustable clamps also contributes to better control and reduces the risk of workpiece slipping. Incorporating vibration reduction techniques can further improve the overall accuracy and surface finish during machining. Paying attention to workpiece material properties helps select the most effective clamping solutions for your specific project. Being aware of clamping forces ensures you use the appropriate pressure to hold the workpiece securely without causing damage. By focusing on effective clamping techniques and material compatibility, you’ll improve workpiece stability and overall machining precision.

Troubleshooting Workholding Problems and How to Improve Performance

Workholding problems often stem from improper setup or inadequate inspection, leading to workpiece movement, vibrations, or inaccuracies during machining. To troubleshoot effectively, first check if your clamping pressure is appropriate—too little causes slipping, while too much can deform the material or damage the workpiece. Ensure your clamps are compatible with the material you’re machining; some materials require specific holding methods to prevent slipping or crushing. Inspect the workholding setup regularly for wear or misalignment. If problems persist, consider adjusting your fixture design or clamping technique. Improving performance involves balancing clamping pressure and verifying material compatibility, ensuring your workpiece stays securely in place throughout the cut. Proper troubleshooting saves time, improves accuracy, and extends tool life. Additionally, proper inspection helps identify early signs of wear or misalignment that could compromise holding strength. Regularly reviewing your clamping method can further optimize grip and prevent slipping during complex cuts. Maintaining consistent workholding techniques is essential for reliable and precise machining results. Incorporating advanced clamping systems can also enhance stability and reduce setup time.

Frequently Asked Questions

How Often Should Workholding Devices Be Inspected for Wear and Tear?

You should inspect your workholding devices regularly, ideally before each use, to guarantee safety and precision. Follow a consistent maintenance schedule, checking for signs of wear and tear, such as cracks or looseness. For high-use setups, more frequent inspections are necessary—perhaps daily or weekly. This proactive approach helps prevent slipping mid-cut, maintaining your CNC project’s accuracy and your safety. Always adhere to manufacturer recommendations for inspection frequency.

Can Workholding Devices Be Customized for Unique CNC Project Requirements?

You can absolutely customize workholding devices for your unique CNC projects. When you need precision and flexibility, custom workholding and adaptable fixtures become essential. They’re designed to fit complex shapes or unusual materials, ensuring your project stays secure. By tailoring your fixtures, you gain better control, reduce slipping, and enhance accuracy. Sometimes, the right fixture appears just when you realize your project’s demands go beyond standard solutions, making all the difference.

What Safety Precautions Should Be Taken When Adjusting Workholding Devices?

You should always prioritize workholding safety by turning off the CNC machine before adjustments. Inspect the device thoroughly for wear, damage, or looseness to guarantee it holds securely. Use proper tools and follow manufacturer guidelines during adjustments, and never bypass safety features. Regular device inspection helps prevent accidents, and always stay alert to potential hazards. These precautions keep both your project running smoothly and your workspace safe.

How Does Material Type Influence Workholding Choices?

When selecting workholding, you should consider material compatibility and surface grip. Softer materials like plastics need gentle clamping to avoid deformation, while harder metals require robust fixtures for secure hold. Choosing the right workholding device guarantees your project stays steady, preventing slipping or damage. By matching your fixture to the material, you optimize surface grip and maintain precision, giving you confidence with every cut.

Are There Environmentally Friendly Options for Workholding Solutions?

Yes, environmentally friendly workholding options exist. You can choose biodegradable clamps made from plant-based materials, which decompose safely after use. Recycled material fixtures are also great, as they reuse plastics or metals, reducing waste. These options help you maintain secure workholding while minimizing environmental impact. By selecting biodegradable clamps or fixtures made from recycled materials, you support sustainable manufacturing without compromising on safety or performance.

Conclusion

By mastering the mechanics of meticulous workholding, you’ll minimize slips and maximize precision. Focus on fitting fixtures that firmly fix, feature reliable clamps, and favor foolproof techniques. When you troubleshoot thoughtfully and tweak your tools, you’ll turn potential problems into perfect performance. Remember, secure, stable, and strategic workholding isn’t just a detail—it’s the difference between a successful cut and a costly catastrophe. Keep these principles in mind, and watch your CNC projects consistently succeed.